Hot off the press: How Hutchinson uses century-old equipment to make modern race tyres in the heart of France

We go inside the factory which features 100-year-old machines, steam power, and a delightful cafeteria

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

It started with lunch, naturally. For those of us more used to a hasty meal deal eaten al desko, kicking off a factory tour with a three-course lunch of foie gras mousse, slow stewed beef casserole, and a lemon tart was quite the welcome. I was informed that the capacious cafeteria, set in the old factory building, was more for corporate entertainment rather than a true production line canteen, but it was hard to airbrush the image of sweat-streaked factory workers queuing up for a mille-fuille after several hours running a steam-driven vulcanisation press.

We’ve brought you several behind-the-scenes factory visits in recent years, including Miche wheels and the Colnago factory in Cambiago, but this is the first tyre brand we’ve lifted the lid on, so I’m going to play this with a relatively straight bat and go into the nuts and bolts of how a tyre is actually constructed. I was quite surprised to find it was in many ways more akin to clothing manufacture than the hardware we are more used to, but mixed in with a plethora of wonderfully vintage, often steamy machines and a laissez-faire attitude to machine guarding.

Hutchinson may not be the first brand you think of when it comes to tyres, but it has a storied history in not only the bicycle space but in automotive rubber, and even has origins as far back as the mid-1800’s producing vulcanised wellington boots with the Aigle brand. Now it produces over a million bicycle tyres a year in its French factory across road, gravel, and MTB. All of its high-performance options, like the Blackbird range and the Caracal gravel tyres, are made here, with lower-tier models produced in Asia.

These pendulous curved mirrors were dotted across the ceiling to allow the workers to see around corners.

- Best road bike tyres: Clinchers and tubeless tyres for cycling

- Best gravel bike tyres: Grippy, fast, and durable options for whatever gravel means to you

Everything is tacky

The first thing that hits you as you enter is the smell. Each part of the factory has a slightly different scent, from the almost acrid notes of the vulcanising presses to the more mellow initial rooms where the raw materials are prepared, but everything smells of hot rubber.

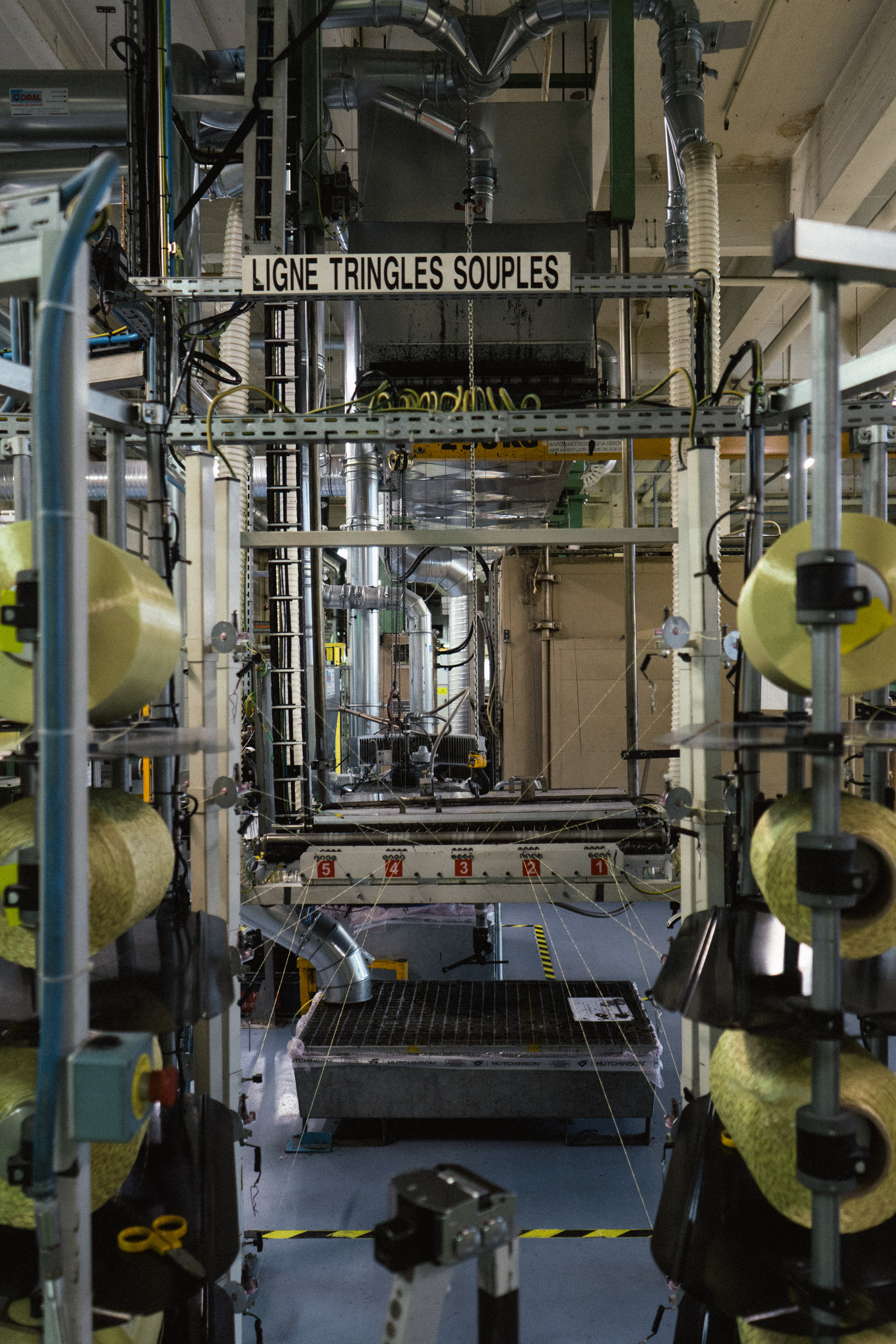

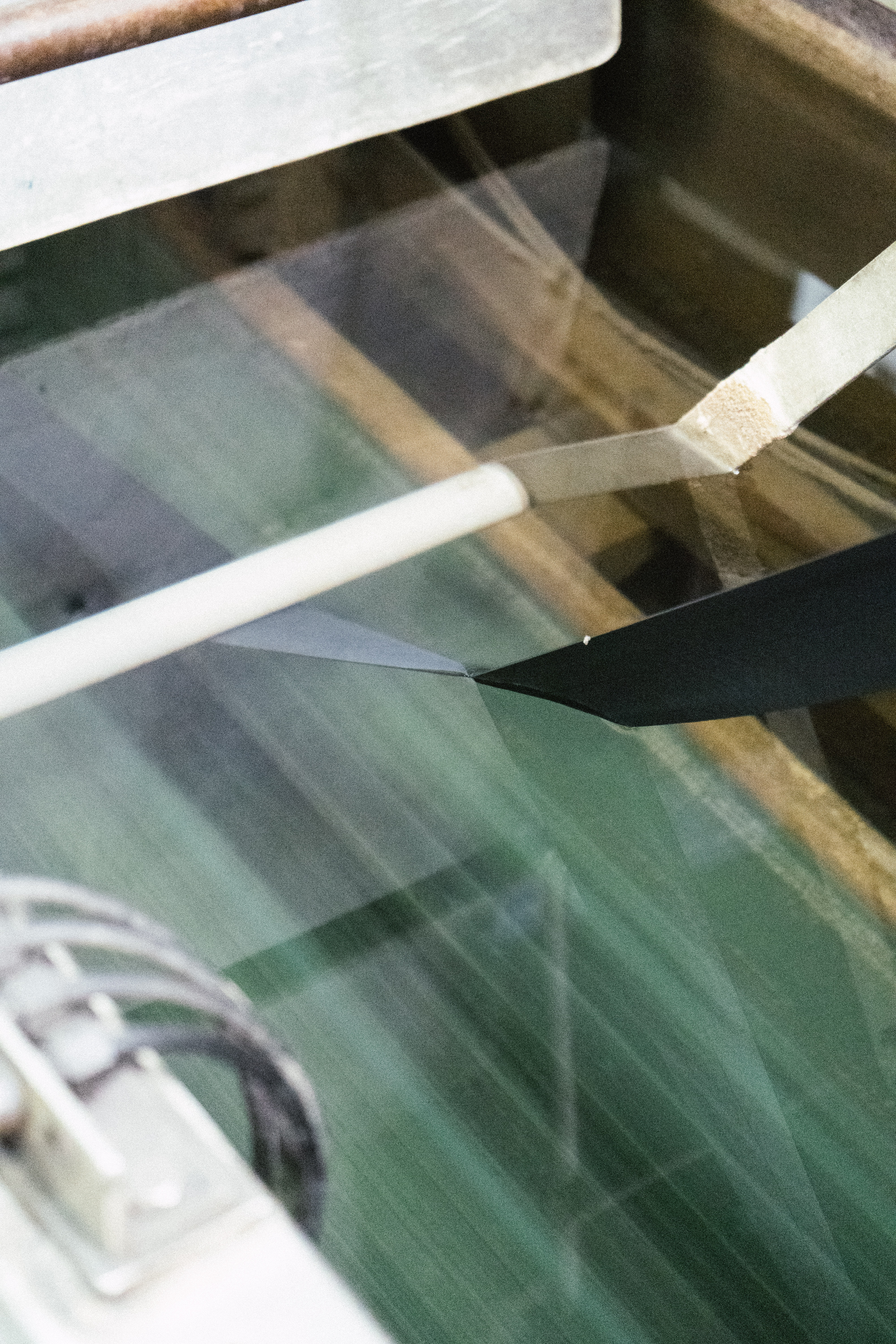

We began with the bead. Rolls of pale, almost translucent yellow aramid fibres are racked up on spools and fed in multiple strands through a coating machine that applies a thin rubber film to the outside, before they are cooled and re-spooled, now black, onto new rolls. This rubber coating is what is referred to as ‘the tack’, and is integral to the whole manufacturing process. It acts as a non-permanent glue, allowing the workers to position and re-position the individual components in the final layup, before everything is vulcanised together in the presses. Without it the tyre would delaminate and fall apart.

The casing fabric, too, gets the same treatment in a separate room. The brand uses either 60 or 120 TPI casing fabrics, plus the addition of various protective layers depending on the model, but these have their tack coating added on a century-old, steam powered machine mated to a modern feed. It’s quite the hybrid, one bedecked with digital screens and the other with exposed, grease-loaded gears and an unnerving warning of something radioactive - I didn’t ask.

On the loom, when we had a nose, was a roll of what looked like basic cotton fabric, and this was destined to be made into the airbags that form railway carriage suspension, the hulks of which were scattered across the factory at different stages of production.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

This casing, much like non-woven carbon fibre, is very strong in one direction, but extremely prone to tearing in a perpendicular direction. As such, it is laid up in two or more layers – usually three – to allow the tyre carcass to resist failure across multiple orientations.

This casing, pre-layered up to the specifications of each tyre model, is then rolled up ready for formation into a whole tyre to be combined with the bead at a later point, along with a blank tread.

Much of the factory has a lovely light pink hue to it. I'm not sure why, but I'm into it.

On the left is the main factory floor, in which are held all the machines and workers.

Having production on-site in France means rapid prototyping is possible, though we didn't enter this inner sanctum.

Fashion-forward safety footwear was the order of the day.

Here are the aramid threads that will eventually form the tyre bead.

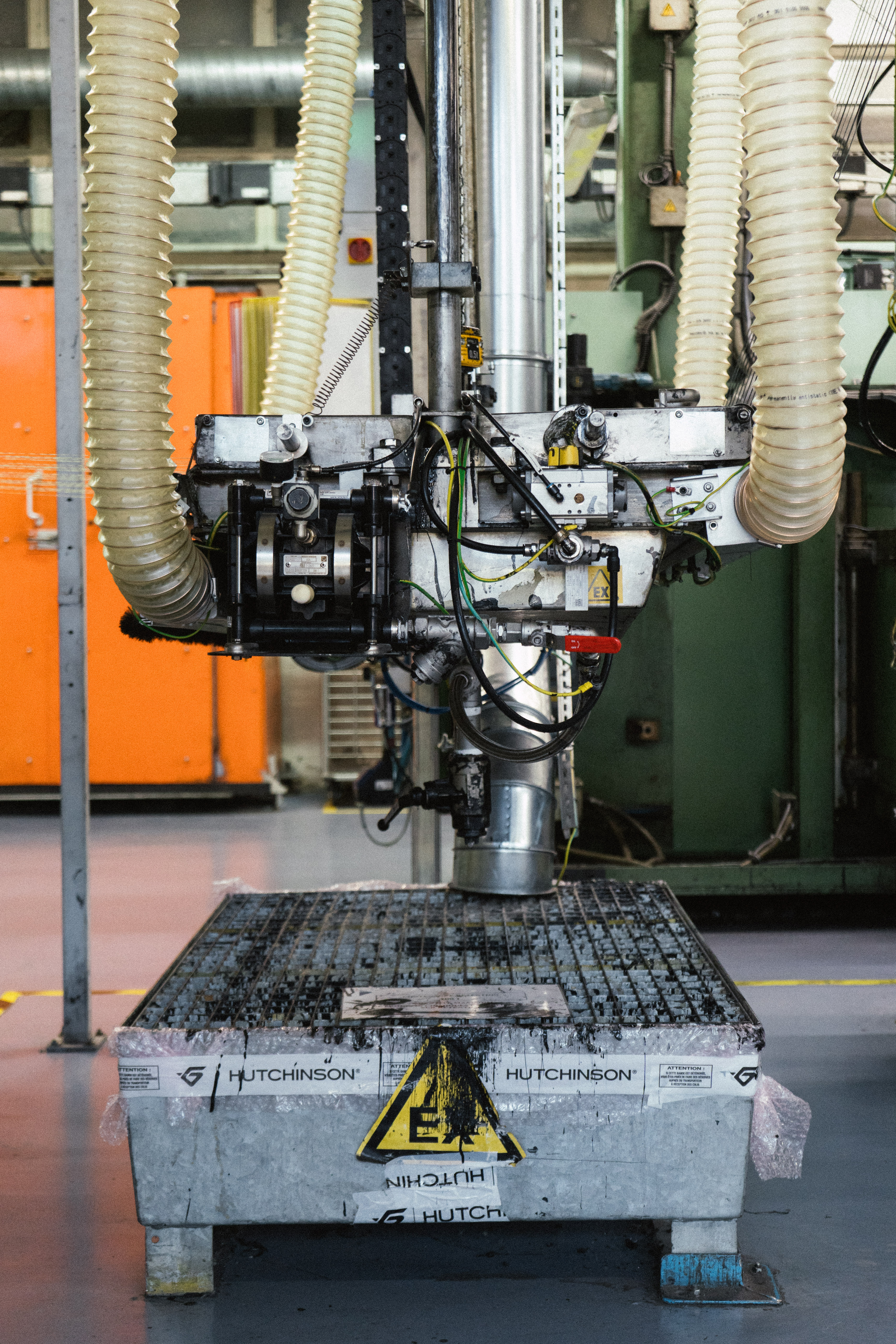

They are slowly pulled into this machine in the centre.

A tacky rubber solution is applied to the threads, allowing them to stick to the other constituent parts of the tyre.

Once coated, they are re-spooled onto fresh looms ready for construction.

This is a 60 threads per inch casing, which also needs its own coat of tack.

It's very flexible, but needs several layers in multiple orientations to resist tearing.

This isn't casing material, but rather what will go on to produce train suspension airbags, but the system is the same. A bulk roll of fabric is fed into the coating machine, which is over 100 years old.

I didn't ask...

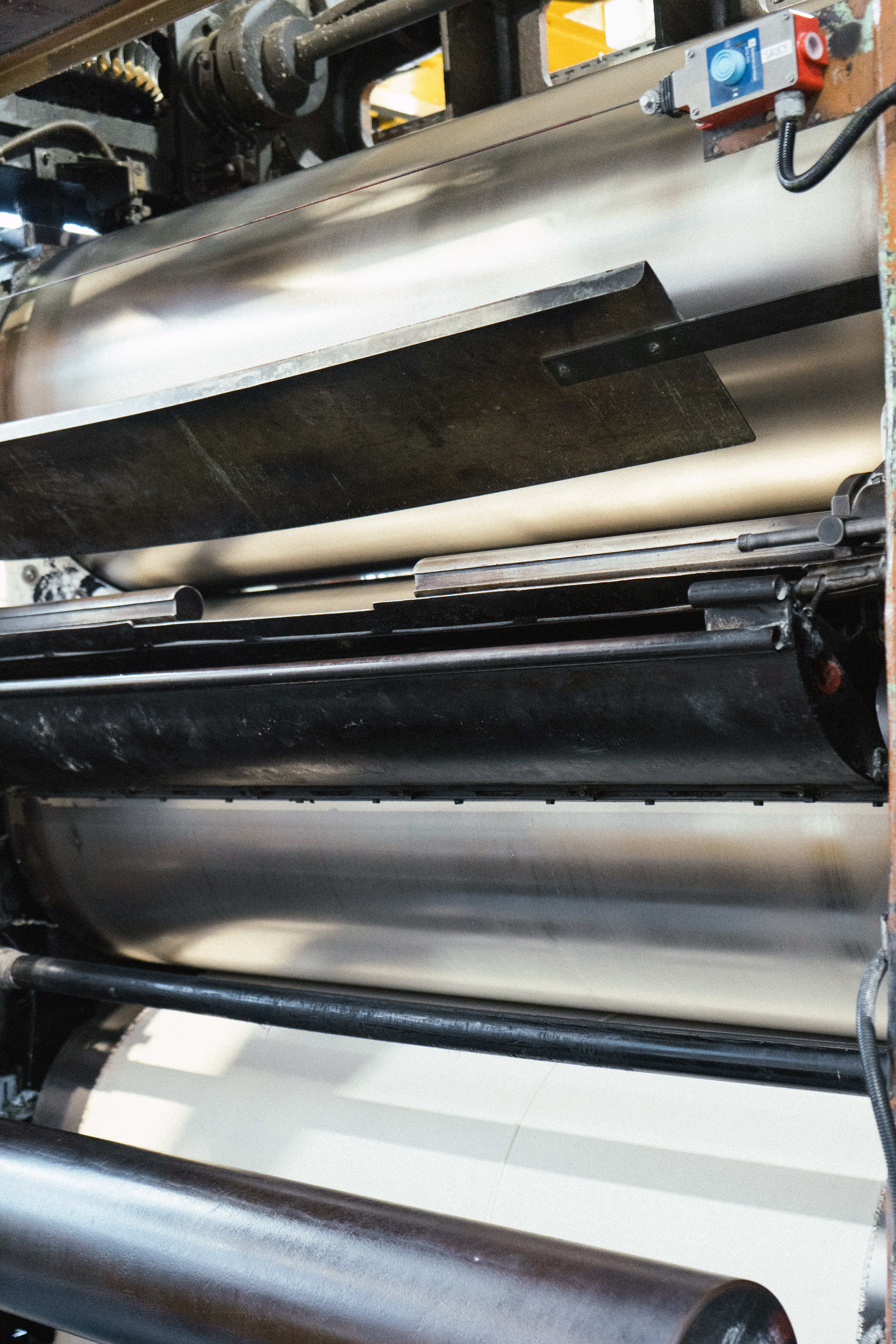

The coated rolls come out the other side of these rollers, ready to be rolled up and sent to cutting.

Here are the train airbags the brand also produces; a little less supple than a race-day road tyre I'd have thought.

I just like that this machine is called Herbert.

As the machines are, in some cases, over 100 years old, the factory has a dedicated machine shop to keep them running.

The raw tread and the three extruders

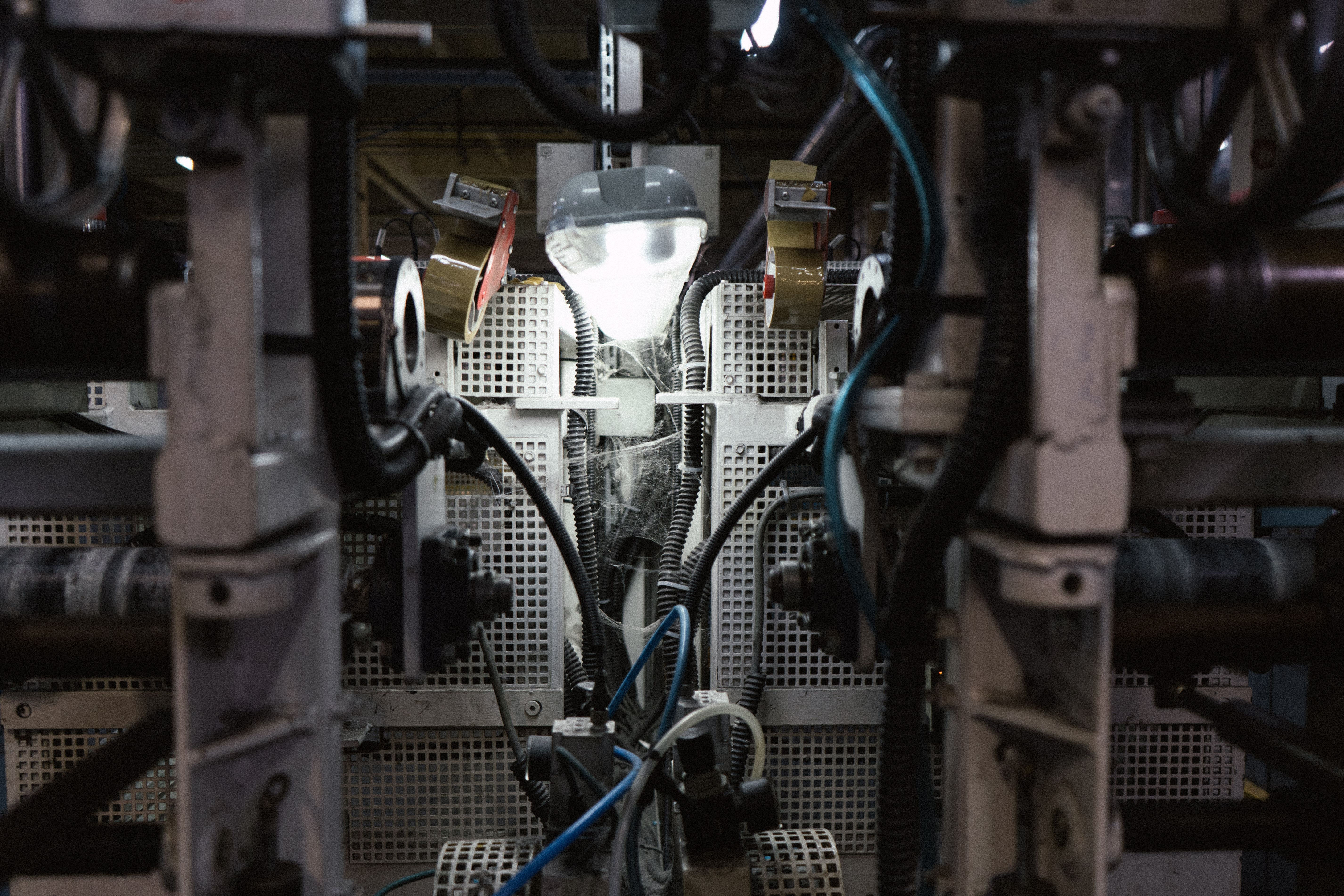

Three faded screw-drive extruders take care of the tyre tread. These, as the name suggests, use a powerful archimedes screw to physically drive the rubber compound out through an initial extrusion phase. Each tread can have up to three different compounds – broadly speaking, a hard, medium, and soft rubber depending on the position – with each extruder taking care of a single rubber compound, mixed to spec on site in a different and more secretive part of the factory.

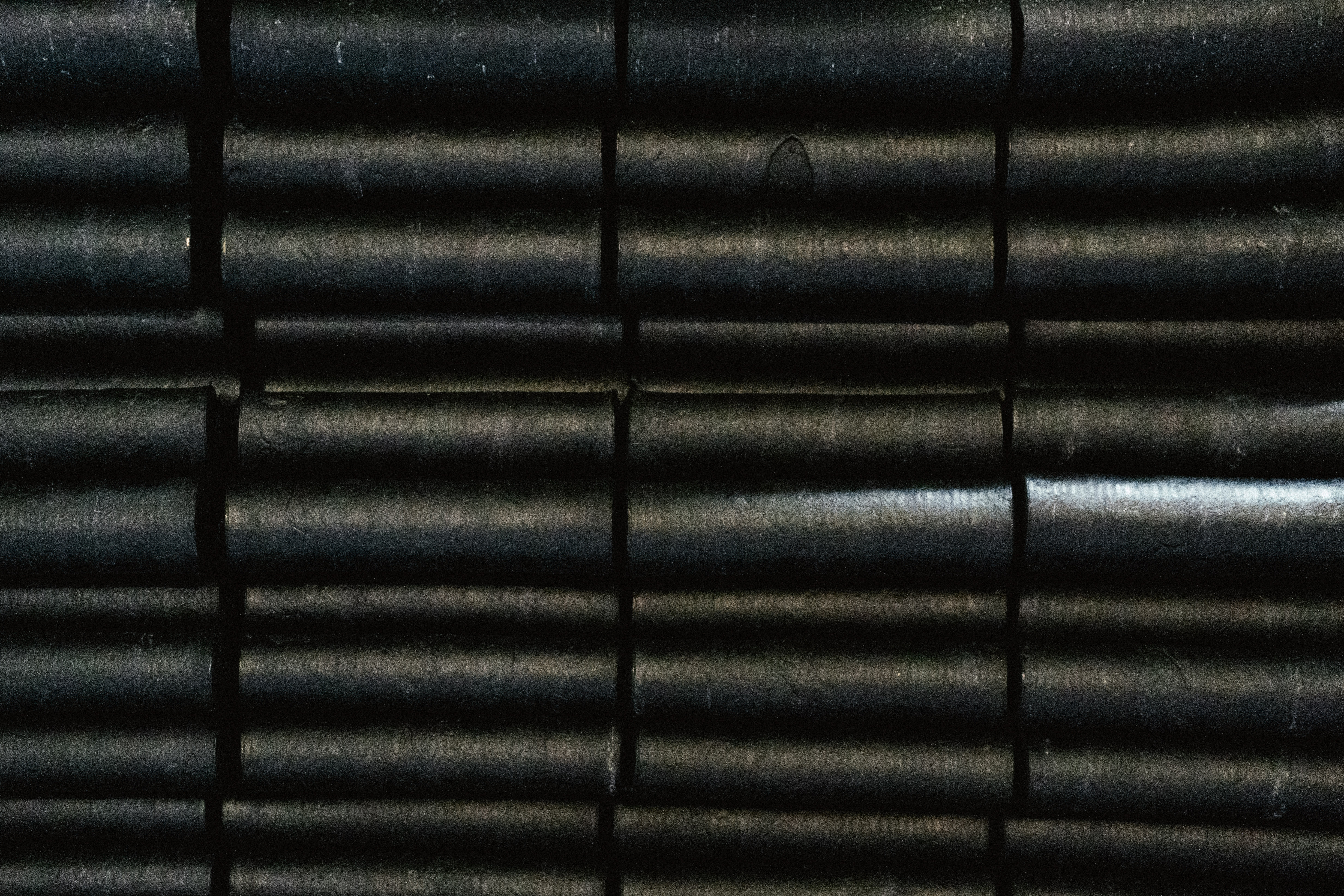

The screw drives heat the rubber compounds up and allow them to be combined and forced through metal dies to create blank rubber treads; think of them as knob-less blanks, with the rubber in the right places (softer on the shoulders, harder in the centre usually), and with enough thickness to fill the voids in the tyre dies during the moulding process later on. Given these are rubber already, they don’t need the tack added, and are racked up after a cooling water bath to be formed onto a tyre carcass shortly.

Every machine has a number, with this control panel for the extruders being No. 87

As you can imagine, the numbers go quite high.

This is the raw rubber compound, ready to be forced through an extruder to make it the right size and thickness for a tyre tread.

The raw, pre-extrusion treads are racked up in stacks.

The vaguely anthropomorphic dies are all racked up too, each one pertaining to a specific tread.

Here's the giant die rack.

This one is for a road tyre, you can see the slot the rubber enters and the smaller size it exits. This is also how I look when I forget something critical.

The friction heats the rubber up quite a lot, so it has a short bath to cool it down.

I am honestly not sure what this machine does. The parcel tape intrigues me.

Handmade by machines

The component parts of the tyre, those being the casing, bead, any puncture protection strips, and then the tread itself, are fed in converging streams onto a segmented drum. The tacky casing is laid down first, then the bead is fed onto the edges before a portion of casing is rolled over by an articulated section to seal it in. Then comes the puncture strip, if present, and then the tread itself.

It’s all very tactile, and while a lot of it is mechanised, the lion’s share is arranged by hand, almost entirely by women. They are, I am told, just more meticulous than men on the whole, which is key for passing the myriad internal QC tests we will get to shortly.

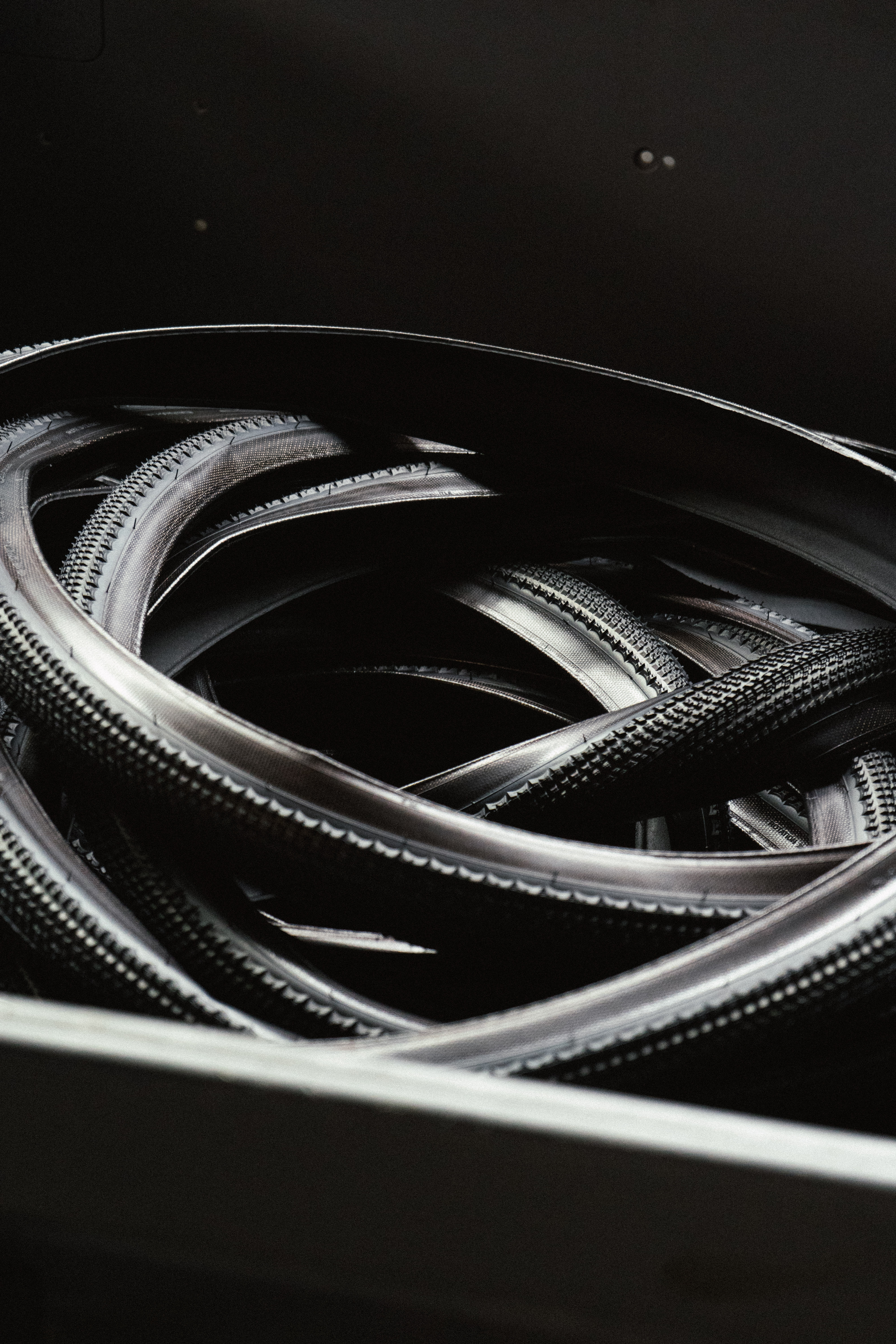

The finalised tyre blanks are then racked up, ready to go into the vulcanisation presses. Each press has a metal negative die of the tyre fitted to it, which clamps the blank in a steam-heated hydraulic press and, over the course of a few minutes, forces the now-vulcanising rubber into the voids to form the final tyre tread.

After a time, the presses automatically lift, revealing a final tyre, still steaming with the constituent parts now vulcanised together and as inseparable as the eggs, sugar, butter, and flour of a cake fresh out of the oven.

Several tyres from each run are then brought to the testing facility for a quite lengthy quality control procedure.

This is where it all comes together. The casing, bead, puncture strip, and tread are all fed in turn onto this articulated drum for arrangement.

Here's the coated casing.

The puncture protection strip arrives on a blue backing.

The factory itself is quite dimly lit, but the ambient light from all the work stations does enough.

While 'factory' might sound automated, the layup of the tyre is labour intensive, and requires a meticulous eye. This latter point is why most of the technicians are women.

The fully constructed blank tyres are then ready for moulding, using these dies. Each one is specific to a specific width of tyre.

The blanks on the left are fed into the steam presses on the right for forming.

They go in flat and floppy, and leave as a fully formed tyre, ready for QC.

The presses are old and still run on steam, which means some impressive plumbing.

Vents under each press degas on each cycling, which makes the press area very atmospherique.

The control panels are wonderfully old school.

The presses appear to run independently of one another, but are set up in pairs.

I'm not certain what this is measuring, but it's well-lubricated.

The fresh tyres are given a short time to cool off and steam a little before being thrown into a hopper for transportation.

These had a pleasing warmth to them, like laundry fresh from the dryer.

The local nature of the factory to the brand means Hutchinson is able to rapidly produce prototypes. Here, a gravity tyre is being produced with an extra reinforcement strip around the bead to reduce sidewall deformation.

Ultimately, no matter how much you try and automate it, tyres remain quite a handmade product, much like a lot of the components on your bicycle.

Testing, testing

A tyre has to do quite a lot without you even thinking about it. It must remain inflated, must not blow off the rim, must provide grip without offering up too much retardation to progress, and be resistant enough to abrasion to last several thousand kilometres at least. It must resist punctures and resist perishing within the lifespan of the product. All of these factors are tested in the lab, in an ante-room off the side of the production floor.

Air tightness is tested by inflating the tyre to its maximum recommended pressure and then measuring air loss after 24 hours, with a 20% reduction allowed. The tyres are also tested to 150% of their recommended pressure to assess their resistance to blowoff, on a rim that represents the least-compatible option while still remaining in-spec to ETRTO regulations. They’re then simply inflated until they explode off the same rim to see quite how much they can handle. I can’t say I recommend you try inflating a 40mm tyre to 8 bar on a hookless rim at home; it makes a hell of a bang.

In order to assess the tyre carcass’s resistance to delamination, a sample is placed on a metal wheel and spends 50 hours hitting a small bump on a roller to simulate approximately 2,500km of wear. A similar setup, with a tyre attached to a flywheel of known mass, is used as a proxy for rolling resistance, with the tyre spun up to a set speed and the run-down time measured after the motor is switched off.

The tyres are stabbed with one machine, and worn away with sandpaper with another to assess their durability, and yet more samples are placed, deflated, on rims in a tank flooded with an ozone atmosphere to accelerate the perishing process and assess the resistance thereof.

If any of these tests result in a failure, either of the internal spec or of the ETRTO standards, production can be stopped and the root cause hopefully identified.

Assuming everything is good, the tyres can then be packaged up and sold. A final learning to leave you with was Hutchinson's best practice for sealing tubeless punctures: Don't spin the tyre, just leave the hole at the bottom and allow gravity to do the work for you.

Probably the result of one very big blow-off test...

This is what I read before bed every night to help me sleep.

This is the puncture resistance machine.

Each sample gets stabbed four times to check for consistency.

Here, test rigs try their hardest to delaminate the tyre.

The rotating drums have a small raised bump that impacts the tyre with each revolution. As the drum is larger than the tyre it hits a different spot each time.

This is the view from inside the blow-off room. The sealant splatters tell a tale.

This rig measures the bead stiffness by expanding the diameter outwards.

A blank mental rim, hookless in this case, is used to mount the tyre for blow-off testing.

Each tyre gets to 150% of its maximum pressure to make sure it stays on, then inflated to the point of failure.

Hutchinson sponsored the very first iteration of the wildly successful Quick-Step team back in 2003.

The last test is the ozone chamber, which accelerates the perishing of the tyre and checks its resistance to cracking.

Will joined the Cyclingnews team as a reviews writer in 2022, having previously written for Cyclist, BikeRadar and Advntr. He’s tried his hand at most cycling disciplines, from the standard mix of road, gravel, and mountain bike, to the more unusual like bike polo and tracklocross. He’s made his own bike frames, covered tech news from the biggest races on the planet, and published countless premium galleries thanks to his excellent photographic eye. Also, given he doesn’t ever ride indoors he’s become a real expert on foul-weather riding gear. His collection of bikes is a real smorgasbord, with everything from vintage-style steel tourers through to superlight flat bar hill climb machines.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.