100 years of manufacturing - Miche factory tour gallery

A techy look inside the Miche factory in Northern Italy's cycling heartland

Miche (pronounced Me-Ka) is an Italian wheel and component manufacturer situated in San Vendemiano, in North-Eastern Italy. The company has been manufacturing bicycle parts in one form or another since 1919.

A little under a year ago, I interviewed Miche CEO, Gregory Girard, about the Italian brand's business, and in particular, its first foray into WorldTour team sponsorship.

We spoke after Groupama-FDJ switched from Shimano to Miche Wheelsets following 27 years of riding the Japanese giant's wheels.

I was able to visit the Miche headquarters for a factory tour last week, whilst in Italy on another trip, and took a look at where and how the brand's components and wheelsets are made.

Miche produces wheelsets, and the Kleos models are raced on by the Groupama pros, but the company also manufactures track components, which was my introduction to the brand as a youth racer in the UK. Some Pista products are used by the Italian National track squad currently.

It also makes chainrings, cassettes, and cranks, as well as a range of smaller components from lock rings, thru axles, computer mounts and bottom brackets.

It's easy to forget the work and effort that goes into producing components and parts like these sometimes, especially in today's digitally dominated age.

It was fascinating to see the raw materials that get turned into our bike components and the machines and staff that produce them every day in Italy's cycling heartland.

Understandably, I wasn’t allowed to just wander around on the factory floor or take photos of everything, including the testing room where lots of diagnostic and wheel testing machines are.

Regardless, I have tried to capture as much as I can, to provide a rounded look at the setup and what goes into making Miche components.

This represents my original introduction to Miche. The Primato track hubs have been a popular model for a long time.

I looked around the company's showroom before hitting the factory floor, where a range of small parts is on display. I like the drilling on the disc lockrings in particular.

This is the €2000 Attiva Pista SRM track chainset with a bling-looking carbon chainring for good measure.

Miche produces a range of wheels, the Kleos 50 are what the Groupama FDJ riders tend to race on.

From the showroom, it was out onto the factory floor. My guide told me Miche had never, ever had a major accident, and this wasn't going to be the day, so we kept to the main 'path' through the factory, which you can see marked with yellow lines.

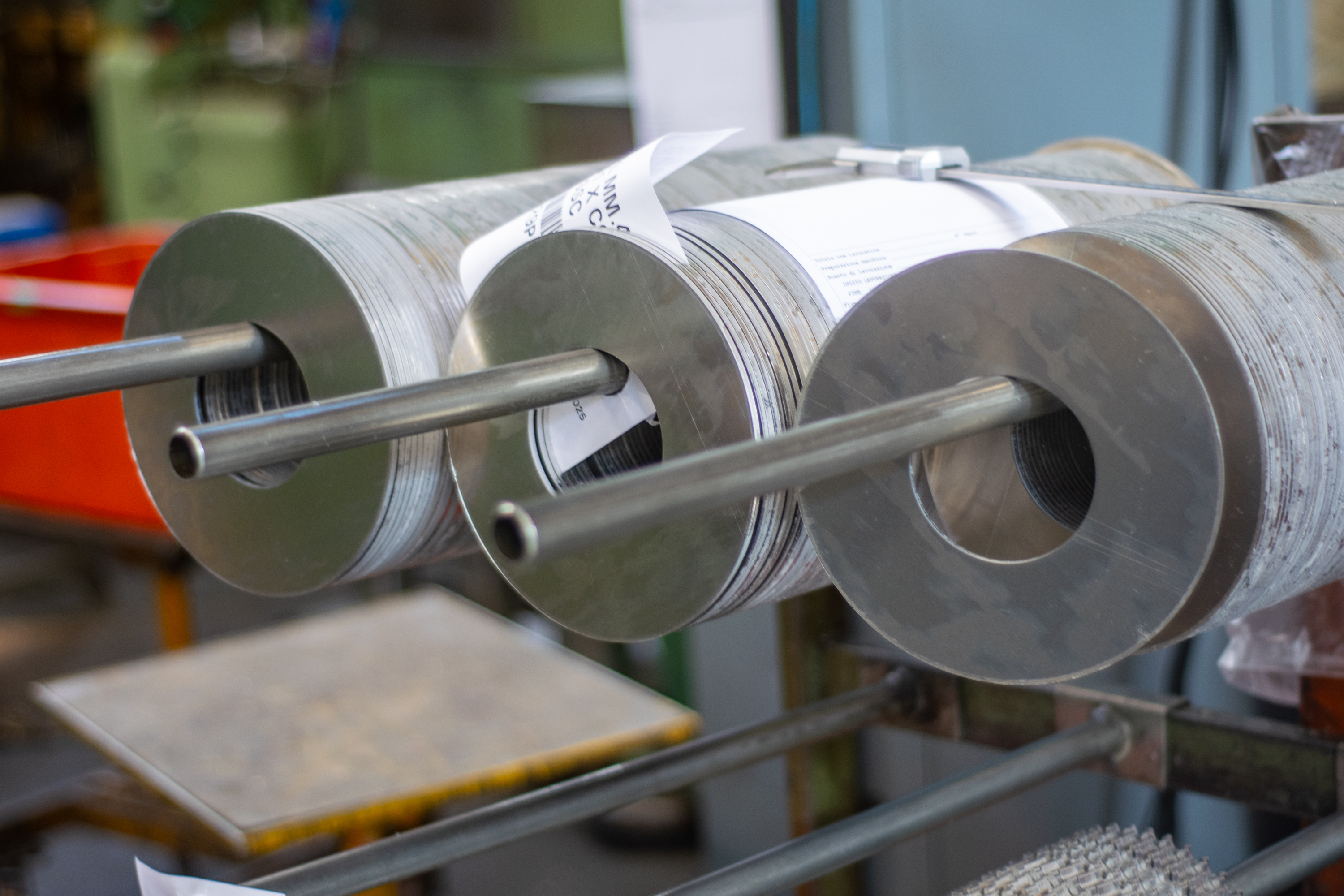

This is some of the raw steel material Miche uses to manufacture its parts, aluminium and steel are used.

These large bars are used to produce chainrings and cassette sprockets. A lot of work turns it into the finished product that ends up on our bikes.

These circular discs are to be turned into chainrings, the pieces of paper have the spec and teeth sizes printed on them

They are then racked like this before being turned into the finished product. Lots of Miche chainrings are CNC machined from 7075 Aluminium alloy.

The machining has been done on these units; there were multiple CNC machines on the factory floor.

It's not just chainrings; these are steel chainset axles. There were boxes of fresh components like this everywhere

Aluminium out-front computer mounts had been punched out of these plates; that's a lot of mounts.

This employee was busy operating a Romi turning centre machine for CNCing parts.

These aren't bike components but change gears for a lathe, stored at the back of the machine, with a big spanner to change them.

A range of CNC cutting tools and holders for all the different jobs on show.

Everybody likes a big load of twist drill bits, right?

As is often the case in factory or manufacturing premises, there aren't so many bike-specific tools, but often more general hand tools for engineering and manufacturing. Spot the Italian Beta screwdrivers

These drums store coolant fluid for the machines. There was a big wall of these, and the factory must get through a lot

We headed towards assembly, QC and the warehouse now, making sure to not stray off the marked safe path.

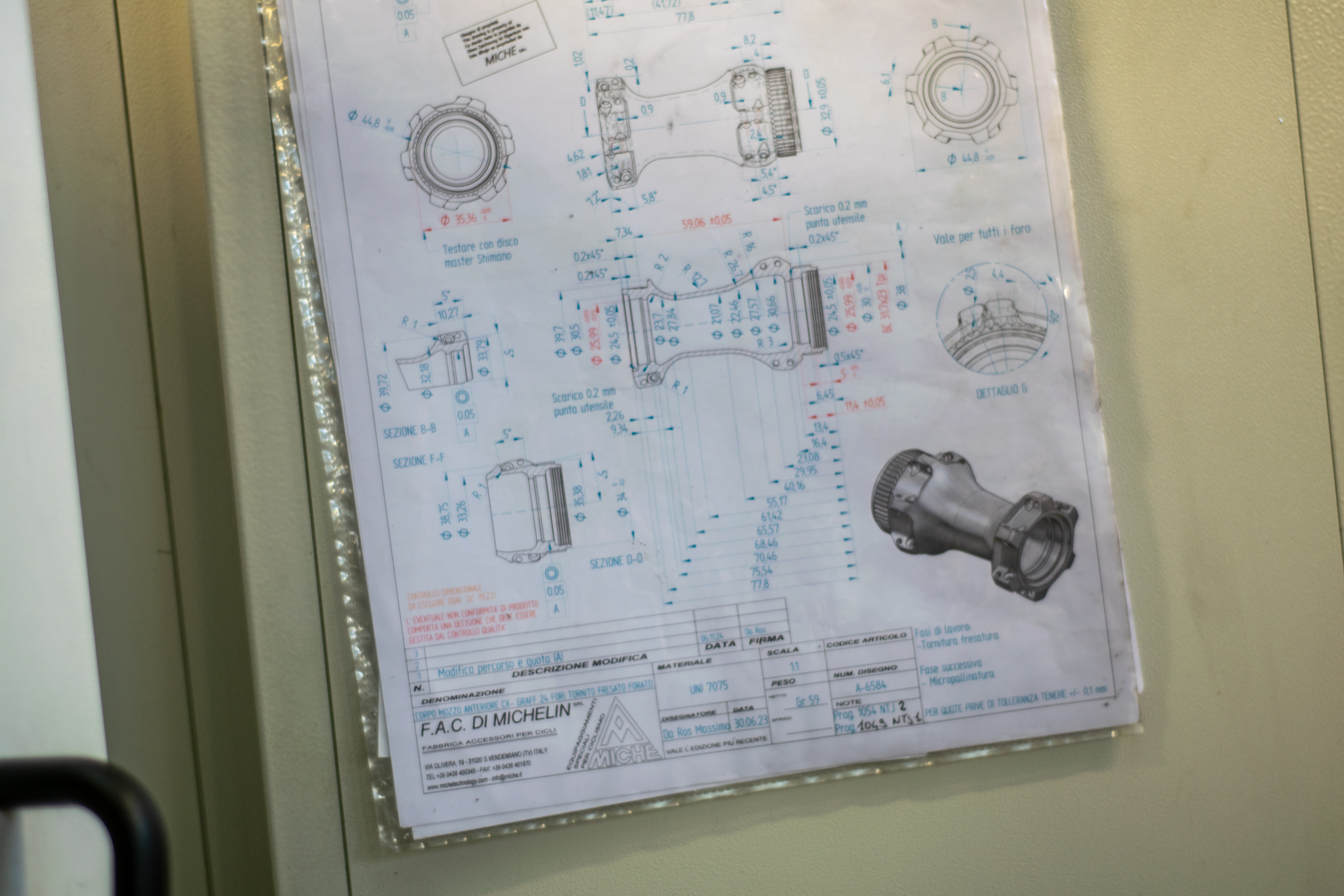

These are the specs for a hub; there are a lot of dimensions to get right, and the hubs are machined on a multi-axis CNC machine from a single piece of aluminium bar.

This was a checking / QC area where certain jobs were checked. Paperweight, anyone?

Japanese Mitutoyo calipers are high-quality and highly accurate.

These hub shells had been anodised, something Miche doesn't do on site, but gets done locally. There's a lot of manufacturing in this region of Italy.

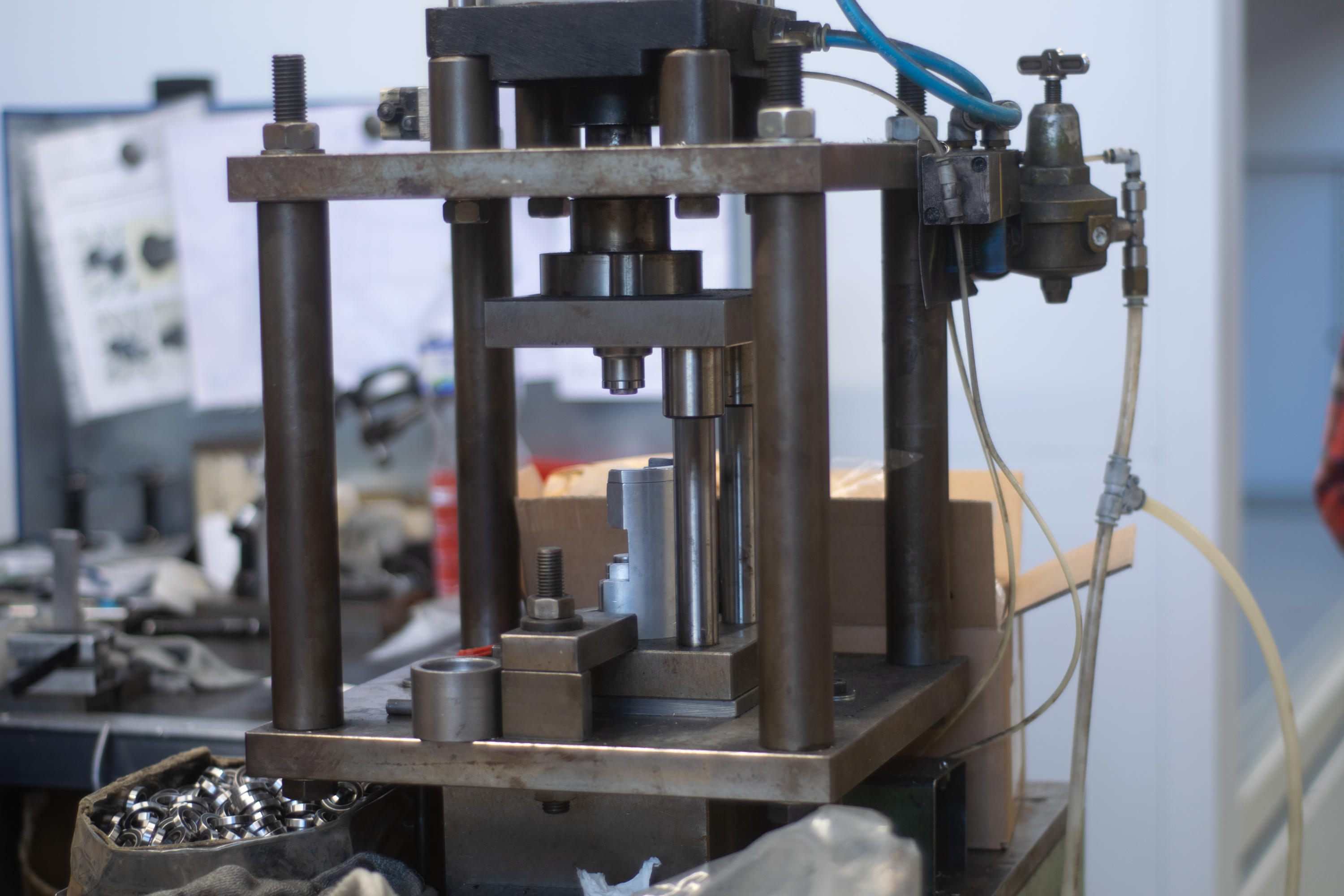

This machine was for pressing bearings squarely into hub shells. Spot the big box of them in the bottom left

At this station, employees were assembling hubs. I kept a distance, they were setting a good pace!

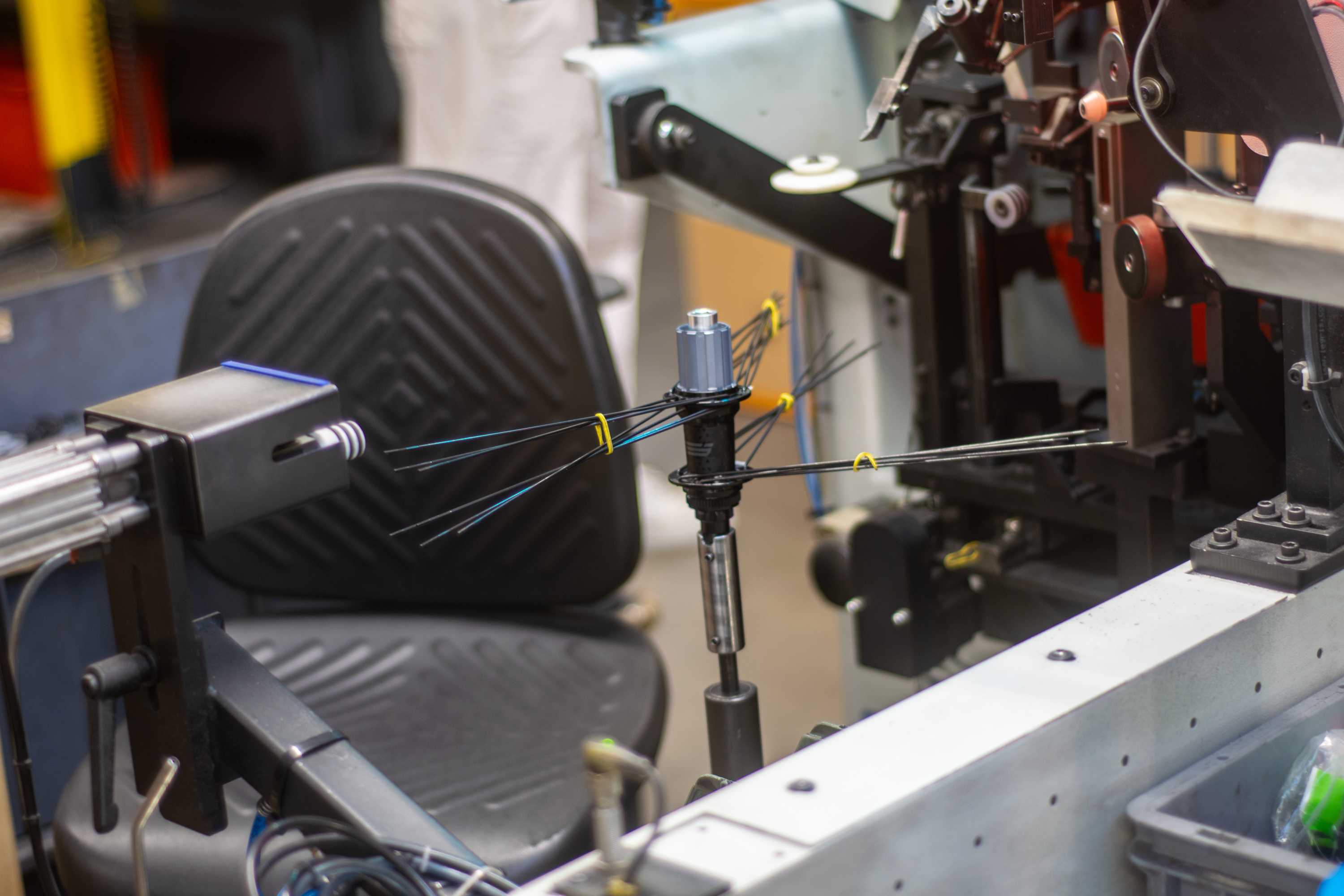

Next up was wheel assembly, hubs are laced with spokes, which are grouped before being assembled by hand with the use of machines.

The hub is installed here, and the wheel builder takes a seat before lacing spokes onto a rim.

Miche's rims come from the Far East, like a great many other companies. Factories there have a lot of expertise and can produce at very high volumes. Miche uses its own moulds for its rims.

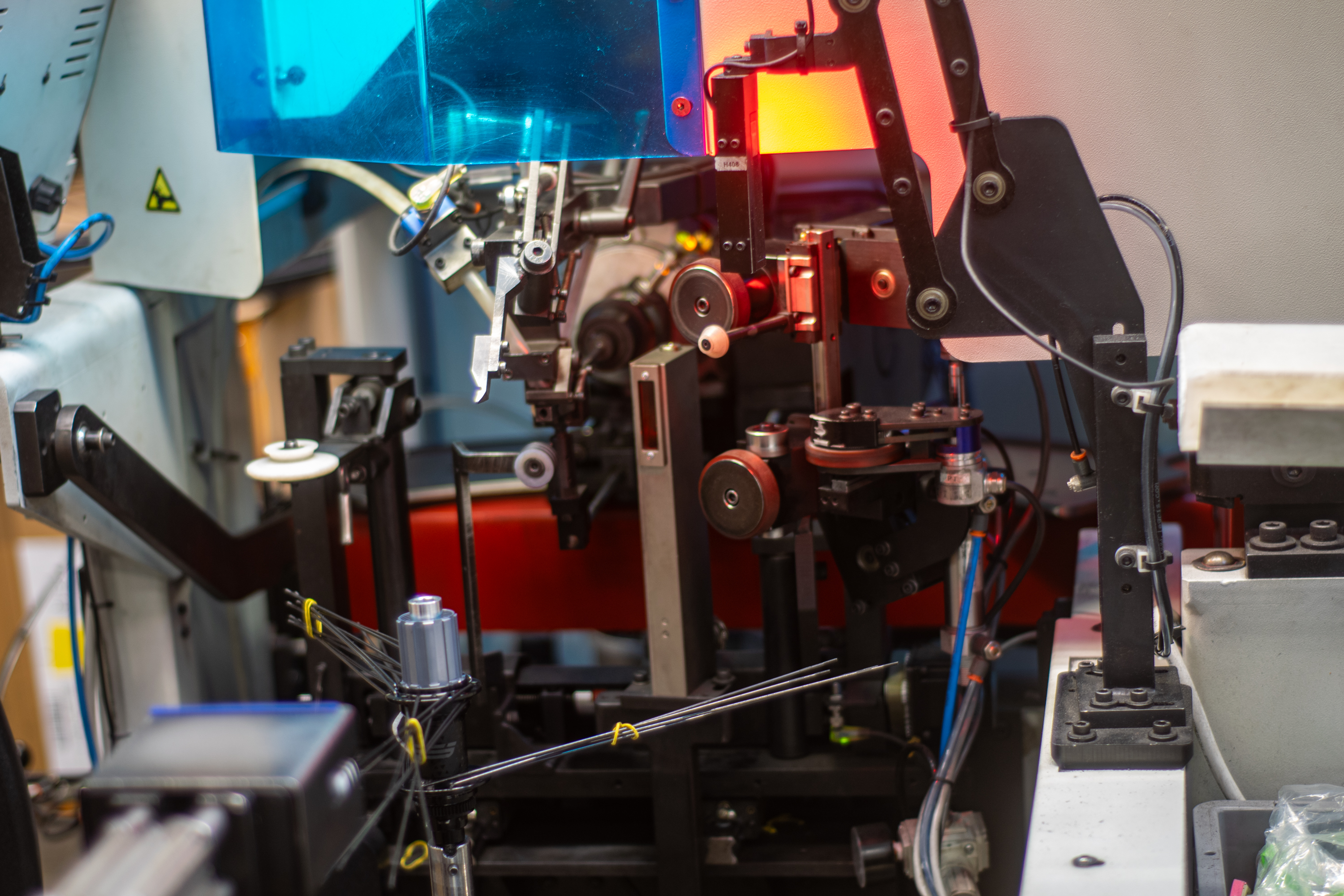

This isn't a transformer, but another shot of one of the wheel assembly machines.

Wheels are assembled to specific spoke tension and lateral and vertical runout specs, and then rolled down this channel once finished.

Miche applies two different layers of rim tape, which I hadn't seen before; this machine makes very light work of it.

One of the final stops was a crankset station, a great many were hanging up overhead.

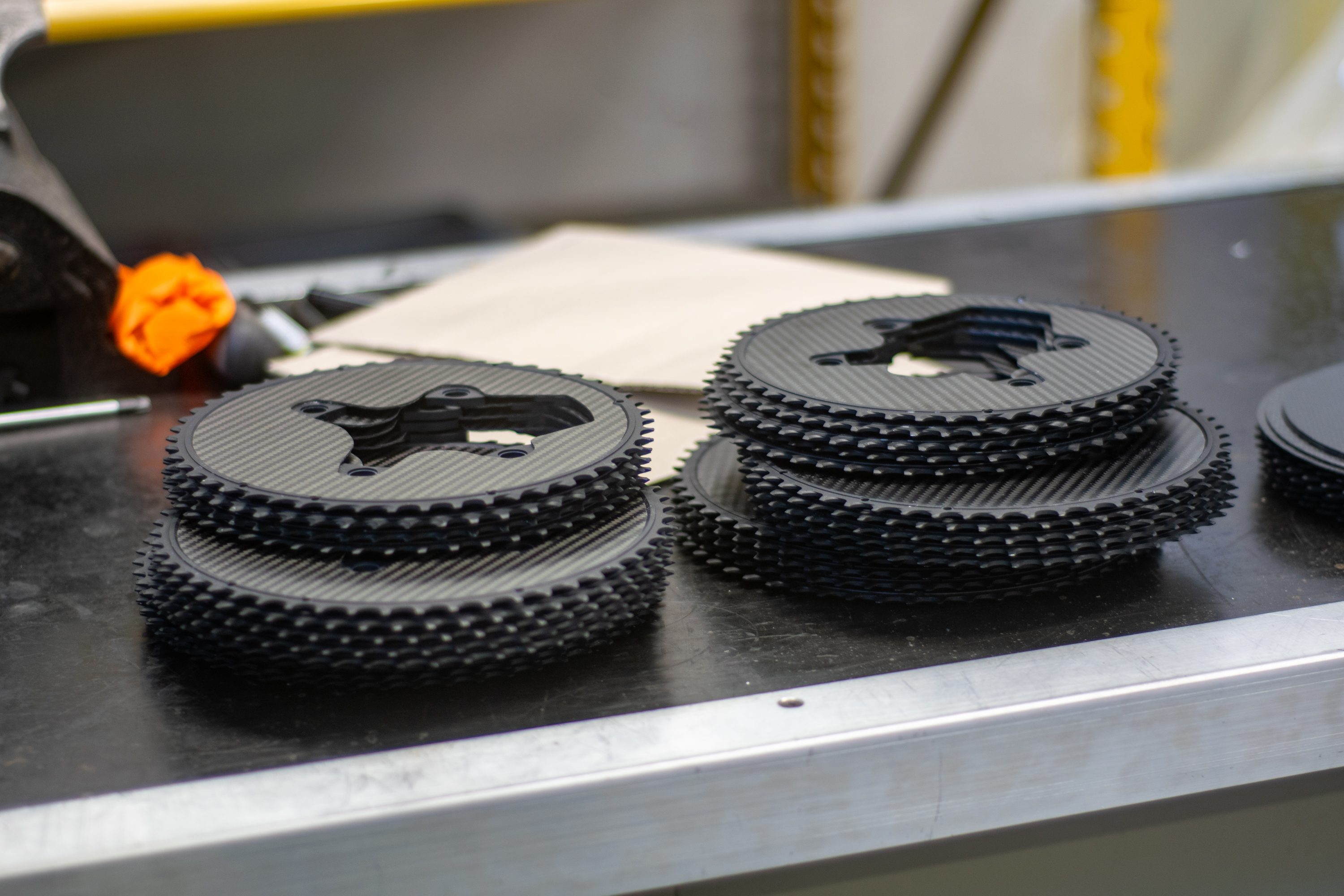

Miche makes a lot of aftermarket chainrings; these are freshly machined ones.

Take my money! Large Miche aftermarket Shimano-compatible chainrings have been popular with WorldTour time triallists of late.

The Miche X2 chainrings pair an aluminium chainring with a carbon fibre outer plate; the two are bonded together and are compatible with Shimano chainsets. These are stacks of the carbon outer plates.

Then it's through to the warehouse and storage area, where row after row of Miche boxes are sitting waiting to go.

All made in Italy, in an area that's a real stronghold for Italian cycling brands and manufacturing.

Lunchtime seems to be taken seriously in Italy; the buzzer rang loudly at lunchtime, and the factory fell silent. We joined some of the Miche workers and went for lunch. Staff members would return, though, to keep making products bearing the Miche name, as they have done since 1919.

Tom joined the Cyclingnews team in late 2022 as a tech writer. Despite having a degree in English Literature he has spent his entire working life in the cycling industry in one form or another. He has over 10 years of experience as a qualified mechanic, with the last five years before joining Cyclingnews being spent running an independent workshop. This means he is just as happy tinkering away in the garage as he is out on the road bike, and he isn’t afraid to pull a bike apart or get hands-on with it when testing to really see what it’s made of.

He has ridden and raced bikes from an early age up to a national level on the road and track, and has ridden and competed in most disciplines. He has a keen eye for pro-team tech and enjoys spotting new or interesting components in the wild. During his time at Cyclingnews, Tom has already interviewed some of the sport's biggest names including Mathieu van der Poel, Tadej Pogačar and Alberto Contador. He's also covered various launches from brands such as Pinarello, Ridley, Specialized and more, tackled the Roubaix Challenge sportive aboard his own rim-brake Cannondale SuperSix Evo, tested over 20 aero helmets in the wind tunnel, and has created helpful in-depth buying advice relating to countless categories from torque wrenches to winter clothing.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.