New Easton Haven Carbon wheels

Promising all-mountain toughness with cross-country weight

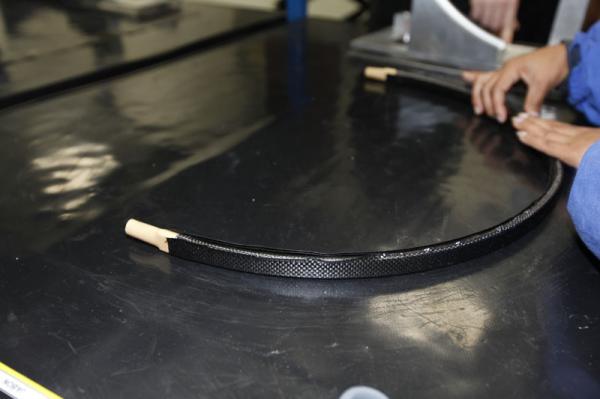

Easton's new Haven Carbon all-mountain wheelset builds upon its existing aluminum model with a feathery 375g true UST-compatible carbon fibre rim that brings the total weight down to a cross country-like 1,450g for the pair while supposedly delivering superior impact resistance, durability and ride quality.

Take flight

Billed as "the first carbon mountain wheel built for going ballistic", Easton says the key to the Haven Carbon rim's toughness is its proprietary Armored Ballistic Composite fibre and resin systems borrowed from the defense industry.

Instead of the more common carbon and aramid fibre mix, Easton uses a stronger and lighter carbon and high modulus polyethylene (HMPE) fibre blend that was originally developed by the US military for body armour and helmets. Holding it all together is an extra tough MRES-B resin that has also been rubberised for further impact strength.

Rim dimensions are similar to the aluminum Haven with a 26mm external width and 21mm internal width to better support wide-profile tires, a relatively shallow 22mm depth, and a solid true-UST compatible outer wall profile for easy and secure mounting of proper tubeless tyres.

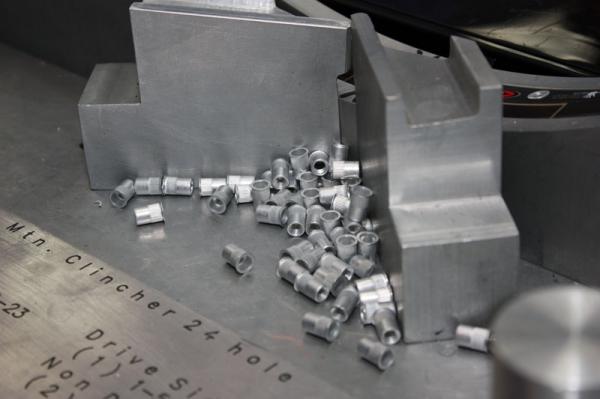

Also borrowed from the standard Haven are the unique riveted-in threaded nipple inserts that are said to distribute stress more evenly than typical eyelets and allow for a thinner and lighter inner rim wall.

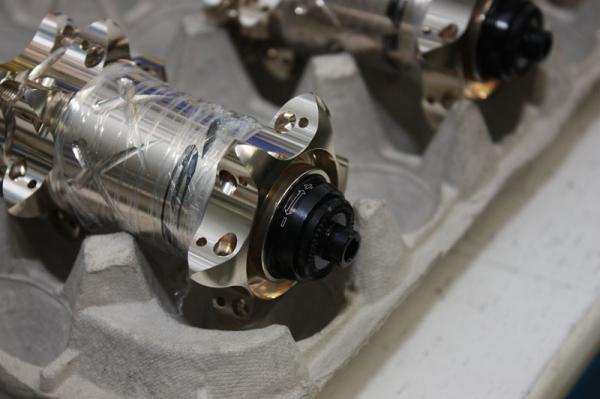

The convertible cartridge bearing alloy hubs – which can be configured for 9mm quick-release and 15/20mm thru-axle up front and 135mm quick-release plus 135mm or 142mm thru-axle rear standards – and straight-pull Sapim stainless steel spokes (which are conveniently all the same length throughout for easier repair) are wholly lifted from the standard Haven as well.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

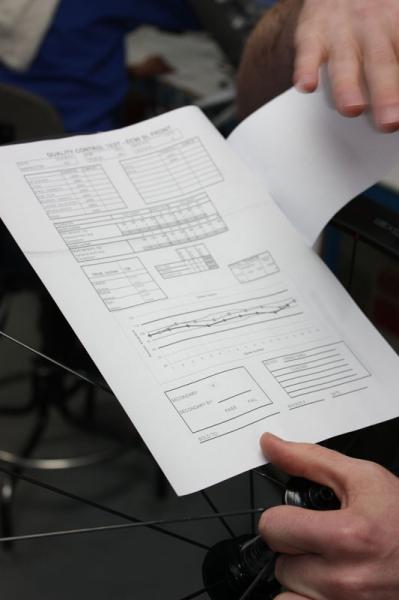

In total, Easton says the Haven Carbon rim is 100g lighter than the alloy version while also lending a more comfortable ride plus bomber durability. In fact, Easton is so confident of the latter that once they become available this summer, every Haven Carbon wheelset will come with a two-year unconditional insurance policy that covers everything imaginable from cased jumps, gnarly yard sale crashes and even absent-minded 'raccidents' so buyers can focus on the wheels' performance instead of worrying about damaging a pair of US$2,300 carbon mountain bike wheels.

Wagon wheelers will be excited to hear that Easton will even offer the Haven Carbon in both 26" and 29" variants.

Not just talk

Impressively, Easton's hype about military defense technology and background isn't just vapid marketing talk. Coming on board about nine months ago as research and development manager was Sayeed Syed, a 30-year-plus veteran of the aerospace industry who was formerly the vice president of composites at Westinghouse and a specialist in ballistics and fibre and polymer systems.

Syed brings with him enviable access to materials, contacts and knowledge in the composites world beyond what many in the bicycle industry can muster along with a background in specifically figuring out how to make composite materials tough and durable (not to mention having Oliver North on his speed dial list and holding the highest possible classified security access for a civilian).

Though even he admits that the ingredients in Easton's new Advanced Materials Systems aren't necessarily exclusive to the company, his experience affords him a more comprehensive knowledge of how those materials can be combined, what materials are available – and who to call to get them – and how they should be processed, engineered and handled to extract the maximum benefit.

Interestingly, Syed says that his new line of work is not only more challenging but also more fun.

"I'm trying to bring aerospace technology to [the bicycle] market," he told us during a visit to Easton's carbon fibre facility in Tijuana, Mexico. "Right now it's all standard materials: everybody is using the same procedure and the same supplier. I'm trying to change the technology to bring in better polymers and better fibres to make things lighter and stronger. [The bicycle composites industry] is mature but aerospace technology is ahead of the game. We want to be ahead of the whole game with systems that aren't even on the market yet."

What this means for the future of Easton – and your future, too

Easton makes no illusion to the fact that the status it once enjoyed in the early days of carbon bicycle components (you all remember the original Monkeylite, right?) has faded a bit but it's now making a more dedicated effort to retake it's "game changing status" with what Syed is bringing to the table.

The Haven Carbon is only the first product to come out of Syed's oversight but product manager Adam Marriott says that an ultra-strong carbon fibre DH-specific Havoc is coming soon – possibly before the end of the year – plus an ultralight cross country wheelset to supplant its current XC One.

Moreover, the new carbon fibre technologies currently in development will also be applied to an all-new range of components though Easton was still very tight-lipped on what that might include or any other specifics.

Either way, Easton's new Haven Carbon wheelset could very well be the product that signals the company's return to dominance in the field and while we weren't to test ride a set during our visit, we'll likely have the opportunity to do so at the upcoming Sea Otter Classic with a proper long-term production test pair arriving shortly thereafter. Cross your fingers.