How it's made: A behind-the-curtain look at Zipp's Indianapolis carbon wheel factory

We follow the construction of carbon wheels from raw material to finished product in Zipp's North American manufacturing facility

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

You are now subscribed

Your newsletter sign-up was successful

In the industrial sprawl north of Indianapolis, in the heart of the American Midwest, a few miles north of the iconic oval Indianapolis Motor Speedway, a monolithic warehouse bears the giant red logo of US component manufacturing giant SRAM. Beside it is the more modest logo of its sister brand Zipp.

It's an ironic order of importance, as inside this vast, hangar-like space is one of the few places outside Asia making carbon bike components at scale. It’s here that Zipp’s Ride Ready SW and NSW wheelsets are made.

A few months ago, Cyclingnews was invited here to see a range of new products from SRAM and Zipp, including its 'smart wheels' and the chance to look firsthand at wheels being made in the flesh is too good to pass up.

Zipp owns facilities all over the world, and splits production between Portugal, Taiwan and Indianapolis. The factory here in Indianapolis, though, offers a rare end-to-end view of the entire wheel-building process, from order to shipping.

The process here not only offers very quick turnaround on road bike wheels, but also allows Zipp to be fully immersed in the production process, integrating it into design and R&D from the ground up.

“You can come up with the greatest ideas, but if somebody can’t make it in a reasonable time and with a reasonable skill set, it’s not a great design,” says Ruan Trouw, SRAM's Factory Engineering Manager, as we stand on the factory floor.

“We’ll typically set a lead time depending on current demand, but we strive to get it done the same day the order is placed – as long as it comes in at a reasonable time. We’ll move those orders through as they come; like you saw on the hour-by-hour chart, we plan the whole day based on customer orders. But for Ride Ready, they essentially jump the line – we get those rims to that specific cell and start building those wheels all the way through to boxing.”

We're being granted full access to all the facets of production, though in some parts of the facility, my camera was forbidden. Zipp has kindly provided its own pictures alongside ours to help illustrate the process.

Below, we outline as much as we can of the production from start to finish, and it all begins in giant freezers…

The Zipp facility's checkered facade is a nod to the speedway, which acts as a sporting centre of gravity for this whole region.

The Zipp 2001 is a piece of bike design history, and continues to have a cult following. The frame is just one part of a rich museum of SRAM and Zipp components decorating the facility here in Indianapolis.

Industrial fridges house the pre-impregnated (commonly known as 'pre-preg') carbon fibre sheets ahead of wheel manufacturing.

“We cut the raw unidirectional into specific shapes, lay them up on tables with the called-for orientations, then cut those sheets into strips," Trouw says.

Those sheets are cut into strips, which move to flow cells where operators hand-place them at specific stations

The strips are then put into a specific layup pattern. This is essentially the recipe of the wheel, before it's cooked.

“Strips get handed down into the cells, the operators have specific spots. It’s broken out into small assembly-line type chunks of work. Each operator will place carbon and pass it along,” Trouw explains.

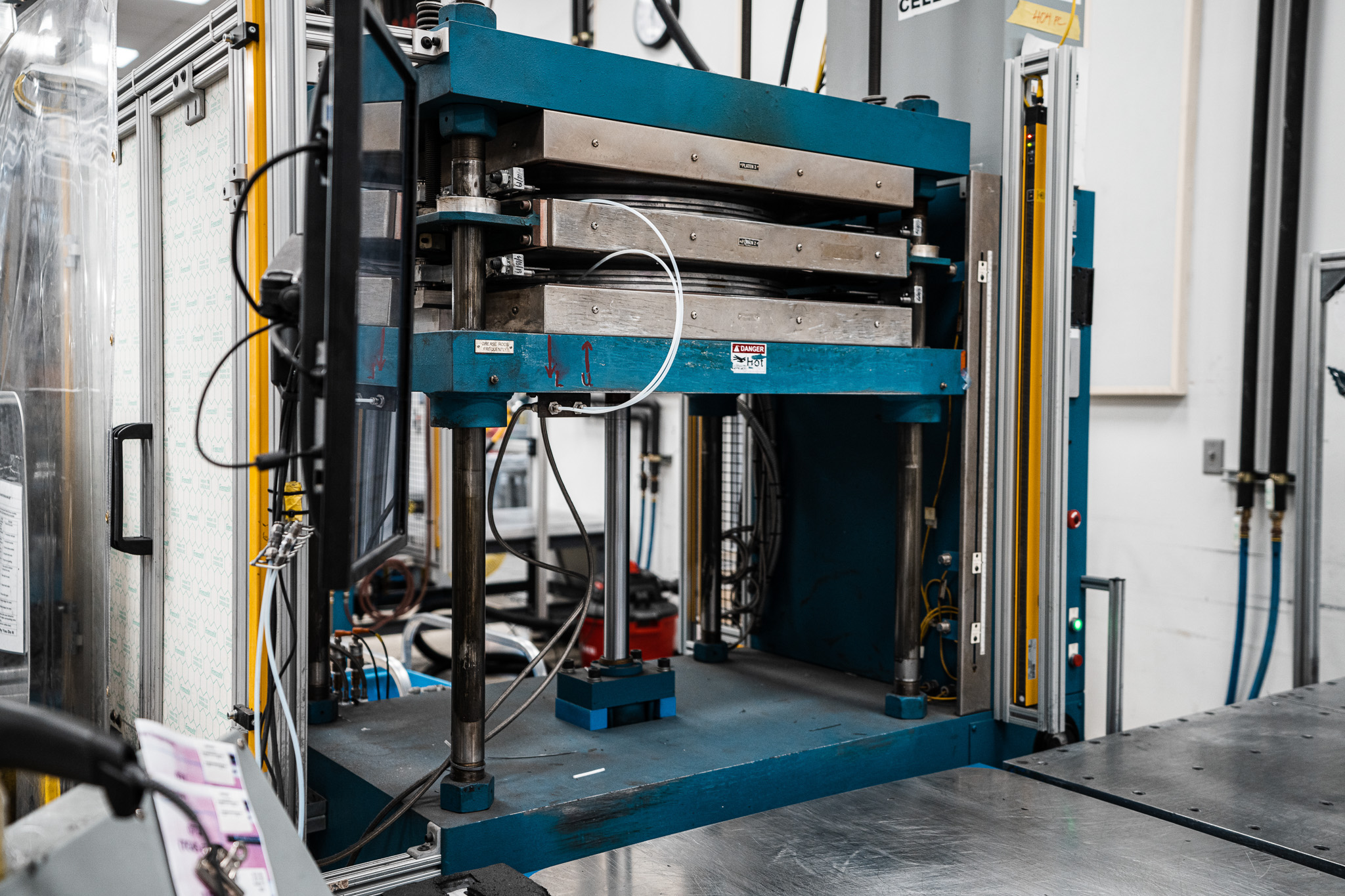

“From there, [the rim] goes into a press and gets moulded," Trouw explains. Zipp uses heat-press moulding to heat and then cure the carbon. Everything is carefully measured and modelled to finite accuracy.

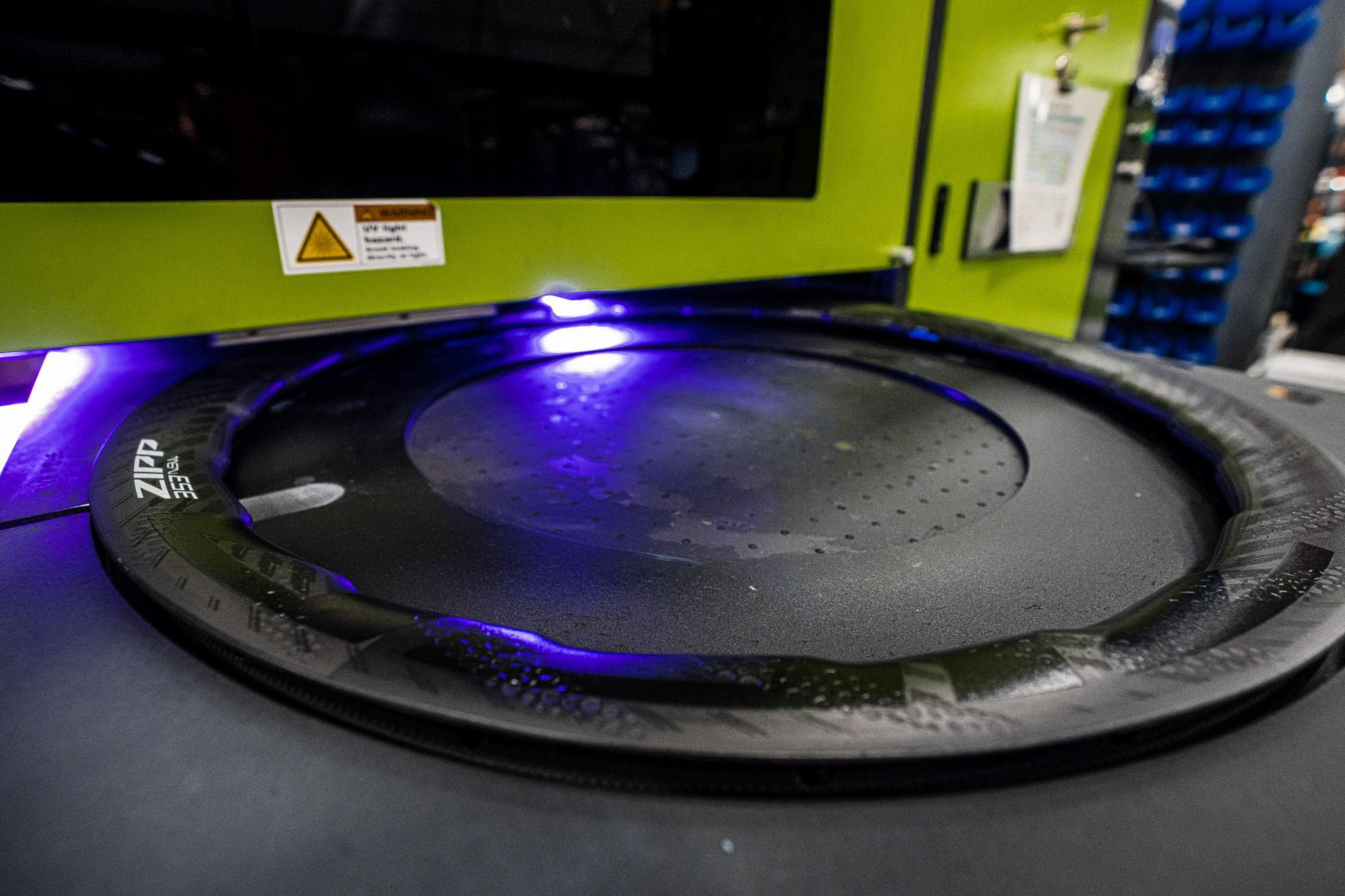

“Once they’re out of the press, we have to go through a deflash process," Trouw explains. "So all of your split lines on the tools will leave a flash line of resin. We have to remove that resin.”

“Once that’s removed, we’ll start with the valve hole first. First drill a valve hole, and then the valve hole is what helps us also locate spoke holes. And so it’ll go into a machine to drill spoke holes.”

“After that, we clean up the rim, remove the bladder, and then as it goes into kind of a final check state," Trouw explains.

"Then that will get fed with the rims down a few different manufacturing lines," Trouw says. "If it gets printed, [it goes to the] printing station first. If it’s a decal rim, it will end up going to wheel build first, and then get decaled."

There are endearing component flourishes across the factory floor. A set of handlebars to steer a trolley, or a section of carbon rim used for a sealant-adding station.

From the market area, rims are matched with hubs, spokes, nipples, and decals in a kitting process before heading to the build lines.

“Printed rims go to wheel build after printing, where they’re laced, built, and finally boxed,” Trouw says.

The Zipp factory is a shrine to the brand's manufacturing and racing heritage. The walls are literally lined with disc wheels.

Peter Stuart was editor of Cyclingnews from 2022 until 2025. Before joining Cyclingnews, Peter was the digital editor of Rouleur magazine. Starting life as a freelance feature writer, with bylines in The Times and The Telegraph, he first entered cycling journalism in 2012, joining Cyclist magazine as staff writer. Peter has a background as an international rower, representing Great Britain at the under-23 level and at the Junior Rowing World Championships.

You must confirm your public display name before commenting

Please logout and then login again, you will then be prompted to enter your display name.