Reap Bikes unveils prototype gravel bike with invisible innovation that improves both sustainability and ride quality

Rideable prototype grows from idea to finished product in just seven weeks

According to Companies House data, Reap Design Ltd was founded in 2014, but only over the past three or four years has the Reap Bikes brand began to establish itself in the road bike space.

Owned by seasoned Ironman triathlete Martin Meir and run alongside his sons, the brand boasts the financial backing of British Olympians Ed Clancy and Jason Kenny, and has garnered itself a reputation for its risk-taking, boundary-pushing innovation.

Its existing v-shaped monocoque Vulcan triathlon bike was already evidence of that, but in the halls of the Truman Brewery this weekend at Rouleur Live show, the brand had a prototype new bike on show. It was conceived less than two months ago, and the brand describes it as the "future of gravel".

Labelled the Reap Type 300 K 5054, it has a name more befitting to a newly discovered asteroid than a bicycle.

At its core, it is an aero gravel bike with wide tyre clearance and interesting shock-absorbing tube shapes. According to one of the Meir sons, Ben, it is laid up using a new form of biological fibre that works alongside the carbon - more on that in a moment.

Gravel bikes with wide tyre clearance are nothing new, but they've typically been aimed at adventure or bikepacking, with relaxed geometries, myriad mounting points, and often some form of suspension. But more recently, there's been a growing trend towards gravel race bikes with their aero tubes and aggressive geometries getting wide tyres too. The new Ridley ASTR RS, launched just last month, is one such example, and tech-savvy gravel racers such as Dylan Johnson are squeezing mountain bike tyres into their gravel frames.

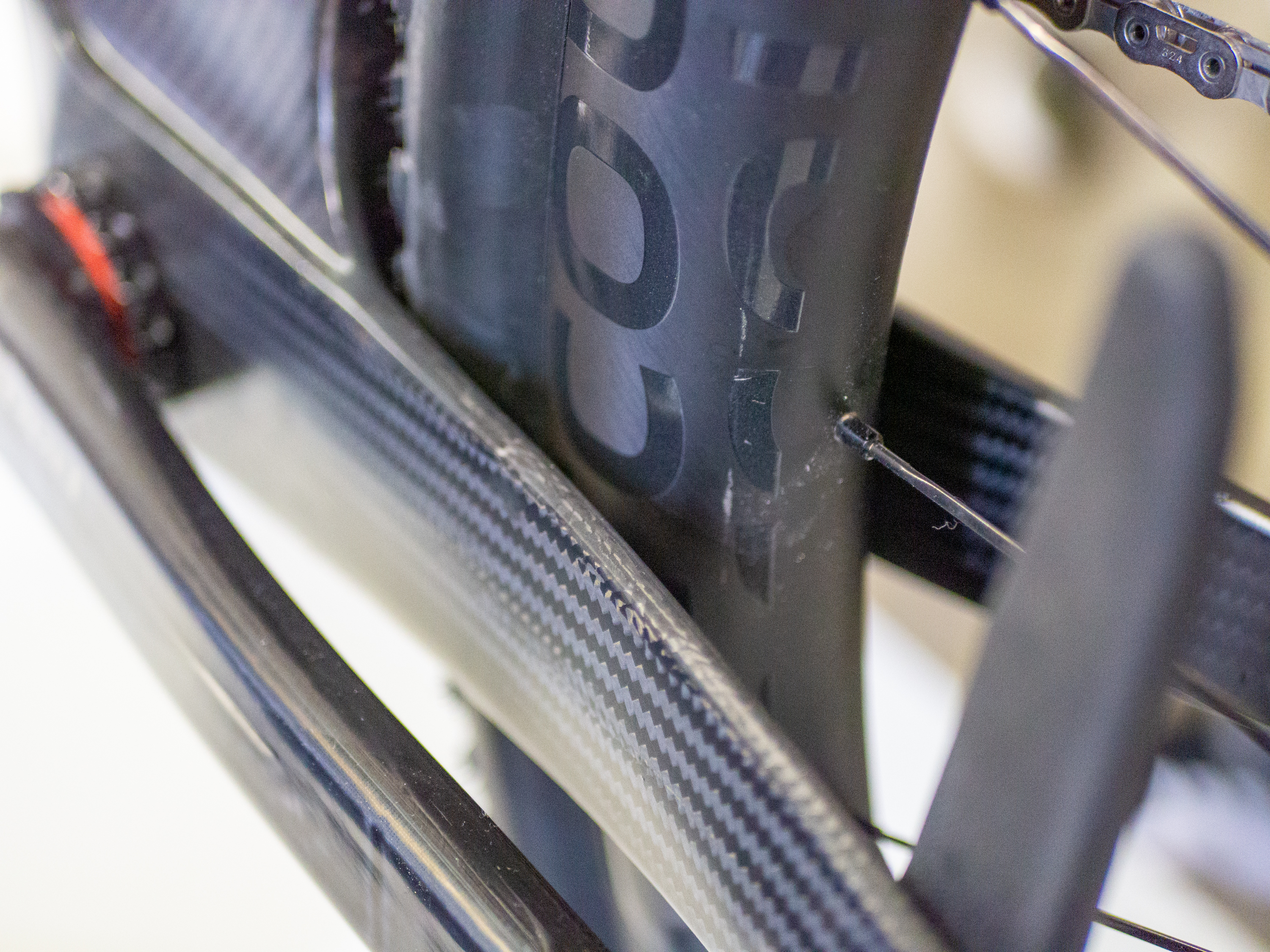

Here on the Reap prototype, there is clearance for 50mm tyres. Notably, that's paired with a standard road-width bottom bracket to ensure ergonomics and aerodynamics aren't compromised by increasing the Q-factor and in turn, the rider's pedalling stance.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

To achieve that, the seat stays are little more than three millimetres thick as they surround the tyre, but their shape then widens, before flattening in the opposite plane towards the rear.

Ben Meir explained to Cyclingnews that these more rearward flat sections, combined with seat stays which extend horizontally from the seat tube for 10cm before angling downwards to the axle, work together to add a small amount of vertical flex in the rear triangle of the bike, in turn increasing the vibration absorption and theoretically power transfer to the gravel road beneath.

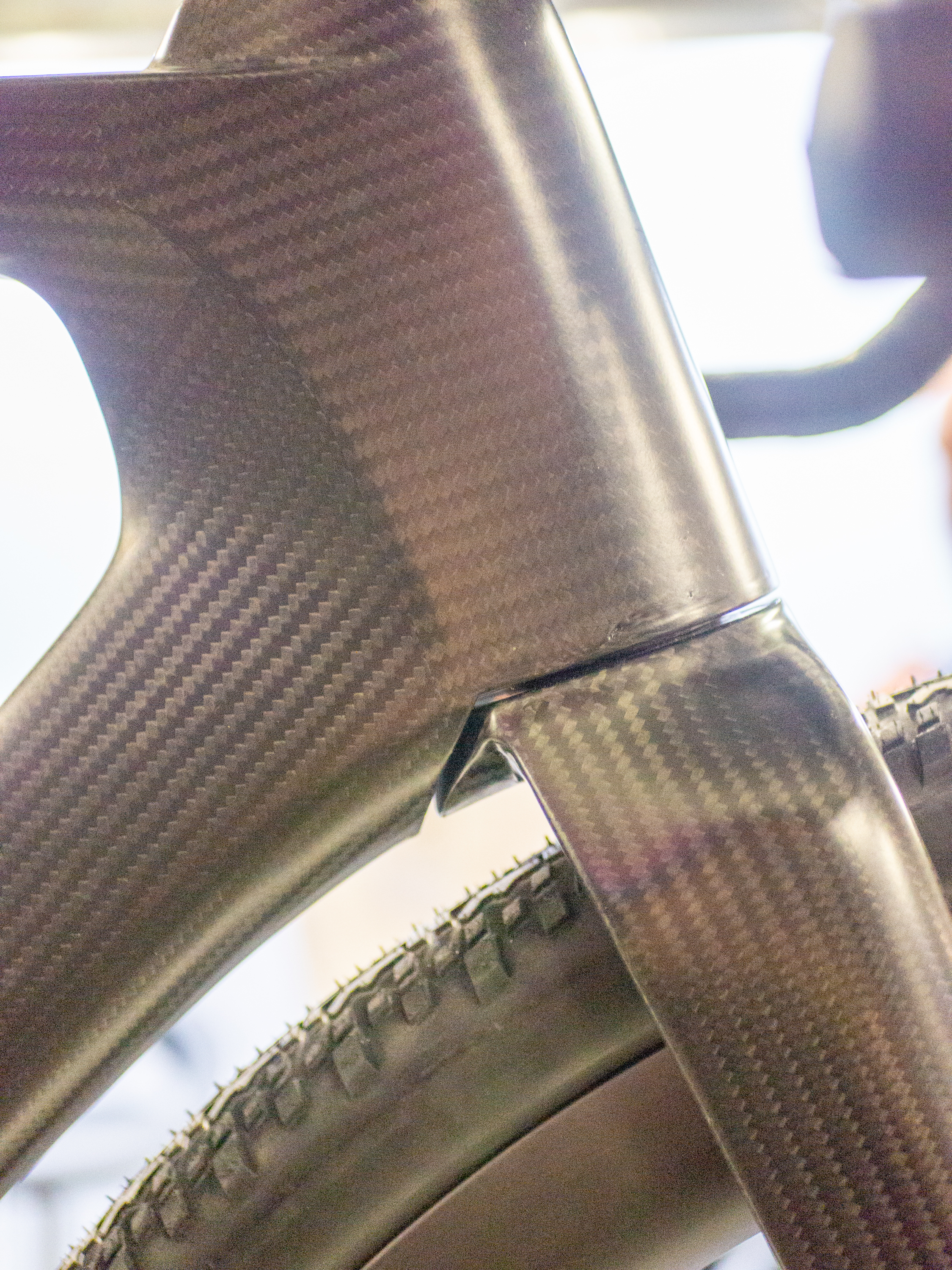

The trick up the prototype bike's sleeve, however, is invisible to the naked eye. The carbon fibre looks entirely normal beneath the lacquer, but as Ben Meir explains, it has been blended with a biocomposite material from French company SCALE Advanced Biocomposites.

The SCALE website states that its "natural fibres can be used with carbon fibre to enhance performance, reduce costs and slash greenhouse emissions."

The company's co-founder, Lance Johnson, told Cyclingnews that the benefits of his material are multifaceted, including significantly reducing the carbon footprint of a bike's production, improving a bike's comfort and ride quality, and even bolstering its ability to withstand impacts.

Up front, the head tube profile has been given an equal amount of attention to detail, and the crown of the fork integrates neatly with the down tube. Brake hoses are fully integrated through a one-piece cockpit and into the head tube of the frame.

On this prototype bike, the seatpost of the frame is fixed to a set height, rather than having an adjustable seat mast as you'd find on the brand's Vekta road bike. This was one of the shortcuts the brand was forced to make in order to get the bike ready in time for the show, but somewhat conveniently, the seatpost height chosen was set to the exact saddle height used by Ben Meir himself.

"I've put a lot of hours into this bike, I deserve it," was Meir's half-joking reply, referring to the toil that he has been through over the past few weeks to get the bike ready in time for the show. Ahead of an industry show like Rouleur Live, it's presumably quite natural for the brands exhibiting to have a late rush to get things ready in time, but for the Meir family, 'late rush' doesn't even begin to tell the story.

The idea to make this bike was conceived less than two months ago, and the brand's Instagram account over the past few weeks has been a video diary of Ben's progress amid autoclave failures and late-night finishes to get it over the line. Just a week ago, there was little more than a fork to show for their efforts.

The bike on display was finished and built up by 11 pm the night before the show, and Ben boasted that he actually managed a night's sleep, something he didn't have the luxury of two years earlier ahead of this same show.

According to the brand, the bike is set for launch in 2025, and Cyclingnews will be first in line to review it when available.

At the time of writing, tickets are still available for Rouleur Live on Saturday and can be purchased here.

Josh is Associate Editor of Cyclingnews – leading our content on the best bikes, kit and the latest breaking tech stories from the pro peloton. He has been with us since the summer of 2019 and throughout that time he's covered everything from buyer's guides and deals to the latest tech news and reviews.

On the bike, Josh has been riding and racing for over 15 years. He started out racing cross country in his teens back when 26-inch wheels and triple chainsets were still mainstream, but he found favour in road racing in his early 20s, racing at a local and national level for Somerset-based Team Tor 2000. These days he rides indoors for convenience and fitness, and outdoors for fun on road, gravel, 'cross and cross-country bikes, the latter usually with his two dogs in tow.