The house of the home trainer: a visit to the Tacx factory

With the European winter fast approaching, there was no better time to visit the headquarters of the...

Tech feature - November 2, 2006

With the European winter fast approaching, there was no better time to visit the headquarters of the largest seller of home trainers in the world. Cyclingnews' Anthony Tan walks the floor at the home of Tacx.

On an overcast October day in central Holland, my visit to Tacx headquarters in Wassenaar was well-timed. Driving from Leiden Centraal station, a stone's throw away from Den Haag (The Hague) and less than ten minutes' drive from our destination, the pitter-patter of light rain was audible on the roof of Product Manager André Möhlmann's silver Audi A4, who later noted the following three months would be the company's busiest.

Outside Tacx HQ, Möhlmann mentioned Wassenaar is the birthplace of founder Moos Tacx, who established the company just over 30 years ago. Just to keep an eye on things, Moos and his family live less than 20 metres away in a modestly-sized house, where he can look out his window, peer over the neatly-trimmed hedges, and see and hear some 30 or so bodies at work.

However, Moos Tacx has retired, and his son, also named Moos, runs the show nowadays, keeping the operation 'in the family' to quote Tony Soprano. "Around 95 percent of what we sell is all made here," says Service Manager Hilko Schravenhoff proudly, who, along with Möhlmann, began to lead me through the factory floor.

"We're actually the largest producer of home trainers in the world," Möhlmann says, before Schravenhoff adds, "Not so many people know this, but we're doing our best to tell everybody!" he says, a light chuckle following.

The distinct aroma of burning plastic abounds in the first part of the warehouse I'm taken to, and if you didn't know it already, it becomes obvious Tacx produce plenty of other goodies besides indoor trainers. Repair stands, bike tools, bottles and cages are all made here, as I watch four plastic bottle tops being pumped out of a machine every 25 seconds.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

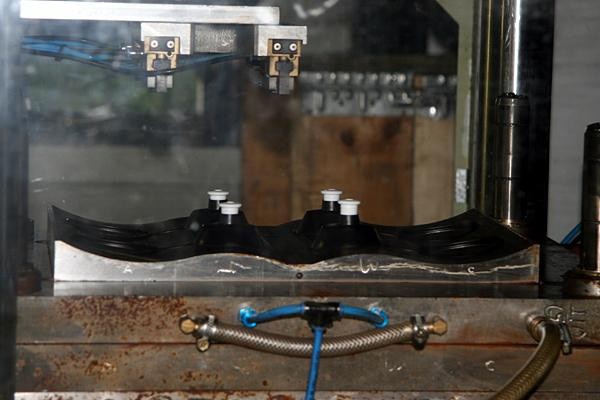

I'm then taken to an area where moulds are created (and repaired or modified if need be), as almost all of the robots are capable of creating more than one type of widget. With (fried) food never far away from top of mind, I grow excited at the prospect of what looks a massive Vlaamse friten (potato chip) fryer, but alas, it turns out to be a place where parts of a mould are drilled while submerged in oil.

Unsurprisingly, an entire space is dedicated to the production of the steel and aluminium parts that comprise an indoor trainer, given this is - and most likely will continue to be - Tacx's core business. Three models of rollers, five types of Cycletrainers (your typical fixed-wheel trainer), and two Ergotrainers and Virtual Reality trainers apiece (both require a power source, with the latter interactive) comprise their extensive 2007 indoor trainer line-up.

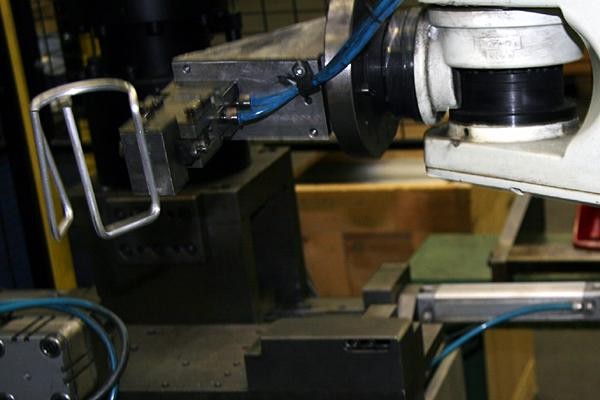

Feeling very much entrenched in a Robocop style world, eagerly snapping away at the various bots at work, both big and small, Möhlmann and Schravenhoff tell me they're particularly excited about the top model Satori Cycletrainer - prototypes were tested by teams including Discovery Channel and Team CSC at this year's Tour de France - and their flagship Virtual Reality trainer, the Fortius.

Back in the boardroom, I was given a brief run-down of the impressive capabilities of the Fortius, where Möhlmann kindly programmed in the Cauberg climb from this year's Amstel Gold Race to begin my ride while the bike was in a 53x12! Dankjewel Andre... [note: Cyclingnews' Ben Atkins will be taking the Fortius through its paces over the coming weeks.]

With my knees splattered all over Le Cauberg, the final place to see was the quality control area and storeroom. Last financial year, close to 90,000 indoor trainers left this floor bound for some 20 countries across the globe, with two-thirds of the output being Cycletrainers. "Unlike many of our competitors, keeping most of the production in-house rather than in China or elswhere enables us to service our customers better and more easily," states Möhlmann, an Tacx employee of 12 years. "We're very proud of this fact, and that we sell more trainers than anyone else."

Taking a photo of woonplaats Tacx across the road, so is father Koos, whose enigmatic figure I thought I saw passing by the window.