Tech: Inside Giant's Taiwan bike factory, part three

Watch as molten metal magically turns into finished frames

This article first appeared on BikeRadar.

Many already know about how Giant is one of very few companies that manufactures carbon frames from raw fiber instead of ready-made pre-preg materials. What isn't as well known, though, is that Giant also uses a similar in-house approach for its aluminum bikes, too. Take a walk with us as we give you an exclusive look at how it's done.

That Giant builds such a staggering number of carbon fiber frames in-house from raw fiber – not ready-built pre-preg shipped from suppliers – is impressive on its own. What's even more incredible, though, is that the company adopts a similar approach with its aluminum frames, too.

Giant's alloy frames start life about 800km (500mi) north in Kunshan on mainland chain at a facility called Giant Light Metal. Here, Giant actually smelts its own alloys, casts its own billets, and extrudes its own tubing. In other words, when the company slaps its house-brand 'ALUXX' label on a frame, it really is a Giant product and not simply a rebadged item from someone else.

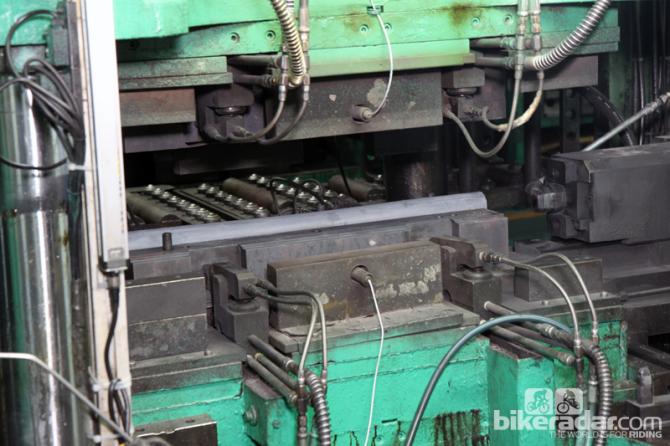

Raw tubing is shipped from Giant Light Metal over to the frame factory in Taichung where it undergoes more rigorous forming operations. As it arrives, the tubing is all round, relatively thick and straight-walled, and far too heavy for use in higher-end bicycles.

Once in Taichung, that tubing is cut to manageable lengths and then forced through a number of dies that reduce the wall thicknesses and refine the grain structure to make it both lighter and more durable than before. As this point, the tubing can already be used to build high-quality frames.

Giant goes further yet, however, with additional shaping that gives the tubing more direction-specific properties. Hydroforming (which uses pressurized oil to push the tubing outward against a steel mold) is the preferred method for higher-end frames while air forming (which uses hot, pressurized air instead of oil) is used for mid-range models.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

In either case, the result is complex tube shapes with very good tube wall thickness control. In many cases, the tubes can emerge from the press with hard points such as suspension pivot mounts built right into the structure of the tube, thus cutting down on subsequent forming and welding steps.

Afterward, tube ends are mitered and deburred, and holes are drilled for water bottle bosses, internal housing ports, and suspension hardware. Each process is done on a dedicated jig to help ensure repeatability and accuracy.

Once the shapes are formed, all of the tubing is prepped for welding. All of the tubing is given a rough polish and is chemically treated to remove any surface contaminants that might otherwise preclude a reliable joint.

Now that all of the preparatory steps are completed, it's time to set everything up in jigs and do some welding. Contrary to popular misconception, these frames aren't built by robots. Instead, Giant employs banks of actual people to lay down the welding rod.

As one would expect in an operation of this size, though, there are some processes in place to boost efficiency. While each frame isn't completely welded from start to finish by one worker, they're not done in full-on assembly line style, either.

Rather, frames progress in a handful of steps through several workers. For example, jigging and tacking is done in one area, one worker might weld an entire front triangle, and then another might do the rear end.

Alignment is checked at several points during the process, too, using a mix of manual gauges and laser sights.

Once welding is completed, frames are sent off for the first round of heat treatment (to T4 spec, for those that are interested), checked again for alignment, then sent for the final round of heat treatment (T6 spec).

After all that, the frames are off for final polishing, cleaning, and prep for painting.

From the time the raw tubing arrives in Taichung to finished product, Giant says an aluminum frame can theoretically be manufactured in about two hours.

In the final installment, we'll see how Giant's workers paint, decal, and install and adjust components on their framesets in record time.

See also: Part one, part two, and part four of the series.