Gallery: Birth of a show bike, part two - Mosaic Bespoke Bicycles

Talking titanium TIG welding with Aaron Barcheck

This article originally published on BikeRadar

Things continue to hum along at Mosaic Bespoke Bicycles with all but one of the frames for next month's North American Handmade Bicycle Show either fully built, at paint, or awaiting just a few details. For Part Two of this series, we shadowed company founder Aaron Barcheck as he welded up a titanium frame and discussed what makes for a good, or bad, titanium weld – and what to look for when shopping for a custom TIG-welded custom bike of your own.

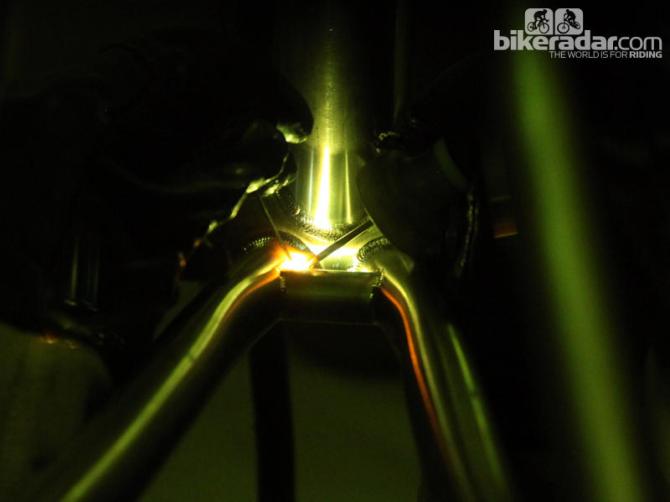

After carefully mitering the tubes and setting everything up in a burly Anvil frame jig – the de facto standard for the handbuilt industry – Barcheck starts with a full fusion weld that uses only the welding torch to join the tubes together. According to Barcheck, this helps ensure full weld penetration for a reliable joint and also provides a more even foundation for laying down the subsequent beads.

Welding rods are used for the second pass, creating that distinctive 'stack of dimes' look that's so coveted with TIG-welded titanium frames.

None of this differs too drastically from the procedure other builders may employ although the manner in which Barcheck goes about it seems particularly stringent. He's militant about preventing contamination and minimizing the damaging effects of heat. Titanium oxidizes when welded in the presence of atmospheric oxygen, which can make the surrounding area brittle and prone to eventual cracking, while excessive heat can burn away too much material, leaving a thin spot in a high-stress area.

To prevent contamination, Barcheck uses a constant flow of inert argon gas that's injected through the bottom bracket shell. Breather holes in the frame are selectively sealed off to create an even and thorough flow of gas through the frame (thus minimizing any residual oxygen that might be lurking in internal crevices and pockets) and there's also a flow of gas coming through the welding torch tip so as to sandwich the work area in 'clean' air.

Barcheck is even careful about how he flips his welding mask up and down so as to not inadvertently send a draft of dirty air toward a still-hot weld area.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

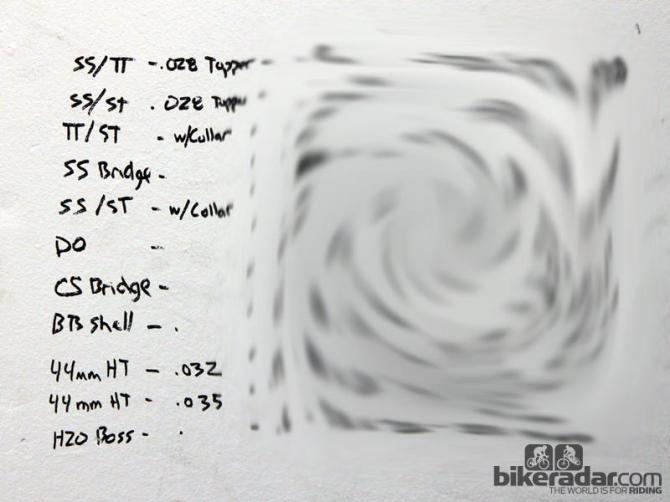

Meanwhile, excessive heat buildup is prevented by the generous use of internal heatsinks, plus specific welder settings and welding rod gauges for nearly every frame joint and tube wall thickness combination. Barcheck also pauses after every few seconds of welding (but leaves the gas flow on in the torch), allowing heat to dissipate.

Barcheck says he's also refined his welding order over the years, not only working from rear to front on each and every frame but also following a very specific sequence on each weld. Mosaic just hired a new welder (stolen away from Moots) and it's only recently that Barcheck wrote the sequence down. Up until then it was a secret hidden away in his head and while we photographed both the sequence and the welder settings, we unfortunately can't share either of them.

We stood watch as Barcheck finished up one of his frames for NAHBS and even with no post-weld finish work whatsoever, the results were astonishingly clean and even with no discoloration to speak of.

Riders looking at buying a custom titanium frame – or even one that's more mass produced – typically won't have the benefit of standing over the builder's shoulder to observe their work, though. It's easy to look at a finished titanium TIG weld and comment on its quality based on how even and tidy the beads are.

However, that judgment literally only scratches the surface of how good that weld actually is. Underlying issues such as poor tube fusion and sloppy miters can cripple a frame down the road and even the telltale rainbow discoloration of a contaminated weld can often be buffed off, leaving customers none the wiser. According to Barcheck, one of the only externally visible signs of a poor weld is one that's undercut – meaning the weld area is actually thinner than the surrounding tube walls instead of being a clean and even fillet.

"Usually when a weld is finished, you can't see what goes into it aside from if it's aesthetically pleasing and maybe that it's not undercut," Barcheck said. "Beyond that, once it's in your media blaster and finish it off, it's hard to tell what it looks like."

"Structurally, there are a few things that go into making a good weld," he continued. "One would be a clean weld with correct back purge and top purge of argon on the frame. Specifically in regards to titanium, if it oxidizes at all, it drops in tensile strength and it drops in yield strength. A dirty weld is not a strong weld. It's going to break at some point."

"Secondly, a non-undercut frame makes for really structurally sound weld. So if you have any changes in wall thickness from one tube to the other that would be thinner than what they should be, you could have a stress riser that might present itself down the road."

Barcheck says anyone looking to purchase a titanium frame – from Mosaic or elsewhere – should do their research on the builder.

"To me, what I would tell people is that it's more about the experience of the welder themselves and to find out if their processes are right, if they're keeping consistent from frame to frame, what type of machine they're using to produce the welds. There's no simple answer."

We've got one more visit to Mosaic scheduled where we're finally get to see some of the finished projects that will eventually make their way over to NAHBS. Stay tuned.

This year's North American Handmade Bicycle Show will take place March 14-16 at the Charlotte Convention Center in Charlotte, North Carolina. Tickets are available for $8-18 per day or $50 for a three-day pass. Attendees can register on the official show website.