Friction Facts: Measuring drivetrain efficiency

Can products like lubricants increase wattage?

Drivetrain products like ceramic bearings that promise lower mechanical friction and higher speeds have been hyped in recent years, but skeptics say drivetrains are already efficient, so any gains aren't significant. But one inquisitive and highly resourceful individual sought to find out for himself exactly what types of efficiency gains could be achieved, and how.

As it turns out, friction does matter, be it caused by a type of product or even a type of lubricant, and Friction Facts founder Jason Smith is producing some eye-opening data.

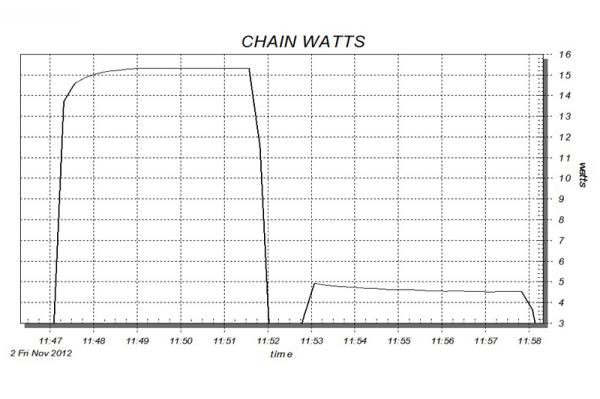

Ten watts from a chain?

Based in Boulder, Colorado, Smith didn't start out measuring the friction of various bicycle components with a business plan in mind. A one-time XTERRA athlete, Smith said he was just looking for every bit of an edge in equipment he could find by doing his own research on whether any of the various products' claimed frictional losses – and associated time savings – were real.

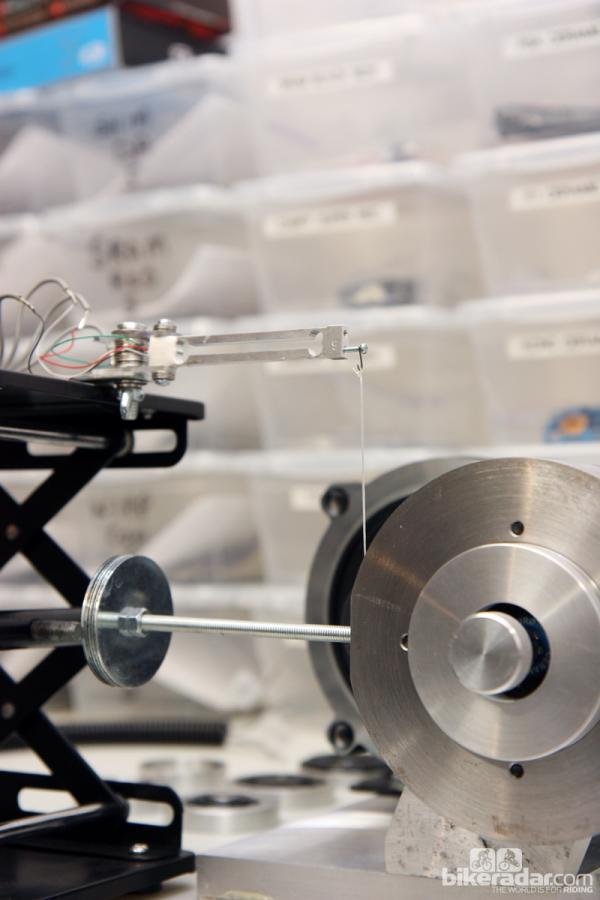

Couple that driven curiosity with a degree in materials engineering, professional experience in testing and measurement devices, and an estimated US$55,000 spent out of his own pocket and – voilà – a test lab was born. In his basement.

Now Smith runs friction-facts.com, which tests drivetrain components and sells the data to individuals.

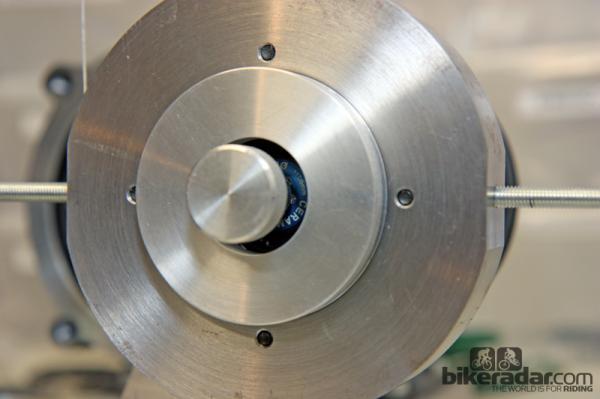

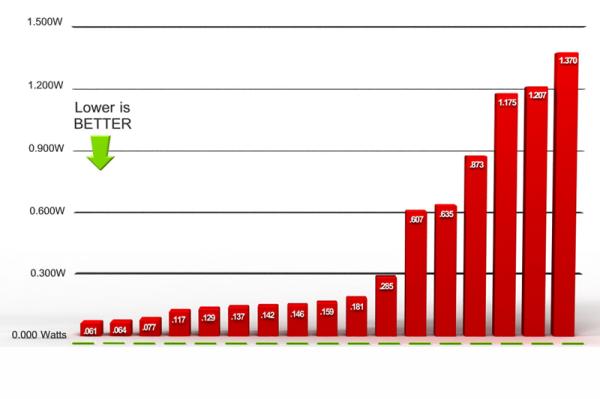

The wattage cost for pulley systems - shown here - are among the drivetrain efficiencies Smith tests

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!

Thus far, Smith has only been testing chains, rear derailleur pulleys and pedals, but hubs and bottom brackets are in the works.

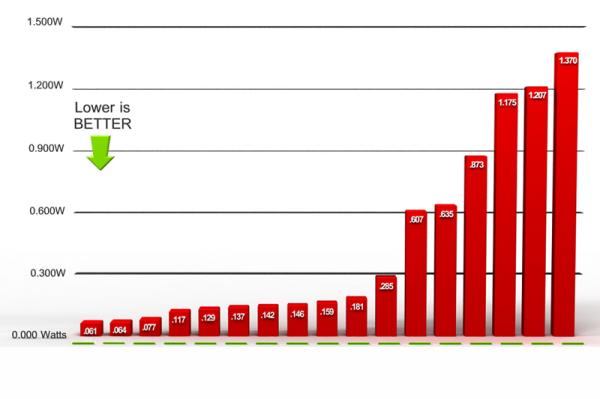

Among his more interesting findings:

-a 3-watt difference between two of the most commonly available new chains

-a 1.5w savings by changing pulleys

-1+w savings by switching to and from certain pedals

All of his tests are calibrated with a constant 250w load, a realistic mark for a rider pedaling fairly hard.

Smith has also been investigating the effectiveness of chain lubricants. There, the results vary tremendously. In fact, Smith says one popular lubricant actually increases drivetrain frictional losses by five watts relative to the factory treatment.

According to Smith, swapping out a worst-case scenario of the least-efficient chain lubricated with a particularly ineffective lubricant for a best-case scenario saves more than 10 watts (when testing at a 250w load).

Not a 'get rich quick' scheme

"I figure that this site will take its own course into the different blogs and the guys that really care about a few watts here and there and see where it goes," he told BikeRadar during a visit to his lab. "I'm just providing data."

However, Smith has used that data to develop his own 'UltraFast' chain, which is essentially the fastest chain he's tested (Shimano's Dura-Ace CN-7901) ultrasonically cleaned and treated with a blend of paraffin wax, pure PTFE, and molybdenum sulfide lubricants. This recipe produces, Smith says, provides the lowest consistently measureable frictional losses of everything he's tested.

Smith sells the UltraFast chains for $89 (a modest $20 upcharge to a stock Dura-Ace chain).

Part of Smith's Ultrafast formula includes running Dura-Ace chains through these ultrasonic cleaners

He sells his test reports for US$5-10. His 'UltraFast Optimizing Service' — where Smith treats your chain to his proprietary strip-and-relube procedure — for $39. His lab services are available at $75 per hour.

Those numbers are drops in the bucket compared what he has invested. Besides his outlay for testing equipment, Smith buys his test samples at retail, and he's careful not to include subjective commentary in his test reports (which could be considered a product endorsement). Also, he's open about how he conducts his testing.

"I'm basically the Consumer Reports for cyclists," he said. "I buy everything myself – there's no advertising on the site and I don't plan on advertising. I hope I can make a little bit of money because I really enjoy doing it."

Some of the power savings Friction Facts has uncovered may not equate to big money in the consumer realm, but even a consistent one-watt gain could be the difference between winning and losing at the top end of the sport. Smith admits that some top team representatives have already approached him.

One watt – or 10 watts, for that matter – may not matter much to casual riders just out to enjoy the day, but that sort of 'free speed' is a huge deal to the right audience.

What's one watt worth to you?

Smith buys all his tested parts at retail to avoid any potential or perceived conflict of interest