Sponsor Content Created With

Understanding the Ursus ethos - a humble commitment to excellence

Italian brand Ursus have been making parts for the bicycle for nearly sixty years

The Ursus headquarters are situated just outside the ancient city of Bassano del Grappa, in the Veneto region of Northern Italy. It's an area that is famed for its manufacturing prowess, and Ursus, along with many other prominent cycling brands, call the region home.

Ursus was founded in 1967 by Sergio Ferronato, and today the company is run by his son Mirko. Ursus is a private company, and one which is without doubt centred around family. Ursus was a famous Gladiator from the Italian adventure films of the sixties; his story and key attributes of dedication and strength provided all the inspiration Sergio Ferronato needed when it came to choosing the name for his company.

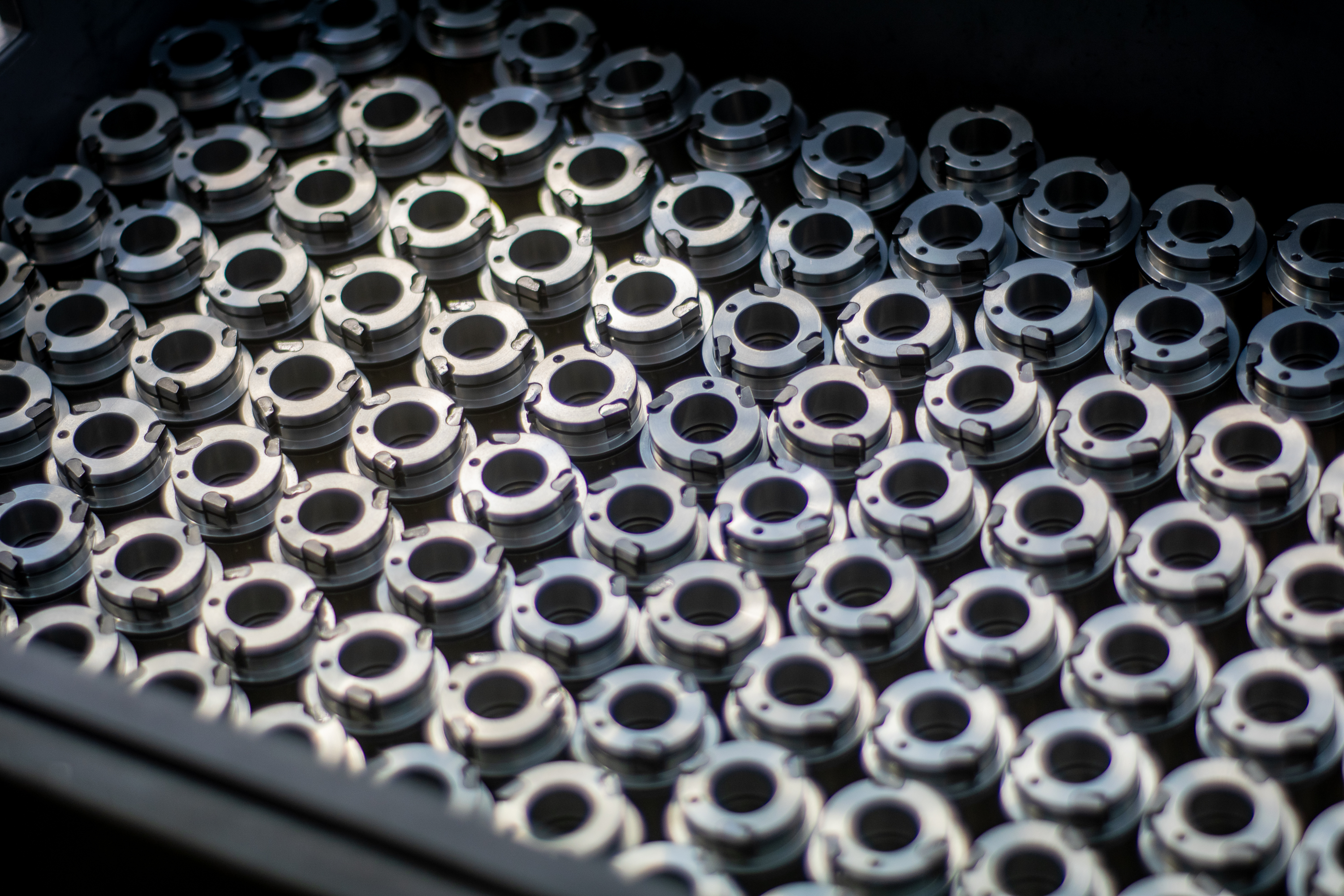

The Ursus story began in the mid-sixties, when Ferronato senior patented a design for a quick-release for saddles. Today, the company's expertise lies in manufacturing, specialising in producing a range of components for the automotive and appliance industries. It also supplies OEM parts to global names.

In the cycling world, Ursus designs and manufactures a range of bicycle components in-house. Quality bicycle kickstands are a specialism, and Ursus also supplies them as OEM parts for a large number of brands. The company is also famous for it’s high end hubs and wheelsets, which it has been producing for several decades.

Ursus has a rich history in cycling, having sponsored many professional teams as well as providing support to teams at lower levels. This is very important to the brand, and many local Italian teams and riders are supported by the company.

At the beginning of this year, Ursus became the wheel supplier to the Dutch WorldTour squad, Team Picnic PostNL. Ursus Proxima wheels helped the team claim victories at the Giro d’Italia and Tour de Suisse, before British star Oscar Onley rode to a fantastic fourth place at the Tour de France on wheels bearing the Ursus name.

Fourth place at the Tour de France is without question an excellent achievement, but Onley's result was unexpected. Results come and go, but Ursus is focused on producing the best possible products it can, whilst staying true to its core philosophies and principles. The brand's history shows it is in it for the long haul, and a new chapter is about to begin.

A quiet confidence in manufacturing excellence

Some retailers order parts, rebrand them, and sell them on, not Ursus. It designs, manufactures, and assembles its components, such as its aluminium bicycle hubs, from scratch in-house at its factories. On-site design and manufacturing ensure complete control over the process, which means that the brand can try new things more quickly and make faster changes to components if needed.

The headquarters also sits in such a strong manufacturing region that most external suppliers are located within roughly a 50Km radius of the factory, making for truly Italian products, and helping to minimise environmental impacts.

All of the energy Ursus uses comes from renewable sources, with a little over a quarter being self-produced by solar systems. Recycled aluminium is also used for a large amount of manufacturing. Respect for the environment and our fellow humans also ties into the Ursus ethos.

Automotive manufacturing is regulated by very stringent standards, and Ursus works in accordance with various ISO and even more stringent IATF automotive production standards.

Whilst not all apply to the bike world, the company's compliance with these standards means it operates on a high technical and engineering level that demands strong manufacturing quality and consistency. For instance, the company keeps stringent records and can check the dimensions and tolerances of nearly all of its hubs, ensuring each batch is to spec and guaranteeing a quality product.

When Ursus entered the WorldTour peloton at the start of the year, the company deliberately provided its race wheels with the rim stickers essentially cut in half. In short, it was difficult to immediately tell what brand of wheels they were; a scannable QR code on the rim itself allowed people to get more information.

One can't help but feel many marketing departments would use the opportunity to increase branding and shout from the rooftops. Ursus decided to take a different approach, quietly, yet confidently, entered cycling's top flight, drawing people in and doing things its own unique way. Safe in the knowledge that its products could and would perform.

Ursus hubs use a dependable, easy-to-work-on design that is valued by mechanics and customers alike. Hub end caps and freehub bodies can be removed in seconds without tools, and the three-pawl freehub ratchet is easy to work on and service.

“We have been here almost sixty years, and you know where we are", said Mirko Ferronato, CEO of Ursus. This is at the core of the Ursus ethos, confidence through manufacturing quality, which means the brand doesn't need or want to shout.

The next chapter

Competition in the WorldTour, cycling's top flight, is relentless. Teams and riders demand the best possible performance, and the level is now so high that an equipment disadvantage is not an option.

All Ursus hubs and wheels are hand assembled, with the laser engraving and bearing installation done on the assembly line, before the wheels are hand-built and checked.

The brand has developed a new top-end road wheel, featuring new patented technology that will be launching early in the new year, building on last year's successes and providing a further advantage to Picnic Post NL.

Ursus has been in business for almost sixty years and shows no signs of slowing down. The company's wheels performed at the very highest level this year, and the brand now sits on the brink of a new chapter in its history.

Races come and go, but Ursus will continue to work with integrity and passion, in the same way it always has.

The latest race content, interviews, features, reviews and expert buying guides, direct to your inbox!